Install a refrigeration unit for the circulating cooling water of the quenching tank

The quenching tank is a container filled with quenching medium. When the workpiece is immersed in the tank for cooling, it must be able to ensure that the workpiece is uniformly quenched at a reasonable cooling rate. It is a container that provides sufficient cooling capacity for the quenching of the workpiece to meet the technical requirements .

The quenching tank structure is relatively simple, mainly composed of tank body, medium input or discharge pipe, overflow tank, etc., and some are additionally equipped with heaters, coolers, stirrers and smoke exhaust fire prevention devices. The temperature of the quenching medium is one of the important factors affecting the quenching effect of the workpiece. Therefore, strictly controlling the temperature of the medium in the quenching tank is a measure to ensure the quality of heat treatment.

There are mainly three types of quenching tanks, oil tanks and bath tanks on the market. Here we mainly talk about the quenching tank. According to the cooling method, the water-cooling type has higher cooling efficiency, but because the temperature of the cooling water needs to be controlled, a sufficiently large cooling pool must be established. At the same time, the circulating cooling of the cooling water also requires the addition of a chiller unit to the quenching tank.

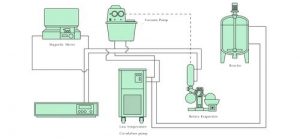

For large production batches, continuous production or large quenching tanks, the heated quenching medium is discharged into the cooling system for circulating cooling. Circulating replacement cooling water consumes a lot of resources, so additional refrigeration units are good news for manufacturers. The refrigeration temperature range of LNEYA cycle refrigeration unit is -150°C to -5°C, which can meet the needs of different refrigeration temperatures. The refrigeration speed is fast and can be frozen to -120°C within 3 minutes after stable operation. LNEYA provides equipment on-site installation and system testing. Users only need to complete the installation of refrigerant and cooling water.

Похожие рекомендации

-

Effect of evaporator instrument for low temperature experiment on refrigeration system

1185According to different models, the choice of evaporators for low-temperature experiment special instruments is also different, such as box-type low temperature experiment special instruments, using water tank coil evaporator; open low temperature ...

Посмотреть детали -

Аксессуары для систем контроля температуры полупроводниковых холодильников

1102В испарителе, поскольку жидкость испаряется в испарителе полупроводниковой холодильной системы температурного контроля, процесс из жидкости в газ, из-за изменения нагрузки, часть хладагента может быть не полностью испарена...

Посмотреть детали -

Low-temperature coolant circulation pump used with rotary evaporator

1298The chemical and pharmaceutical fields are the largest end consumer markets for cryogenic coolant circulation pumps. With the increasing demand for low-temperature coolant circulation pumps in this market, the application of cryogenic pumps in the...

Посмотреть детали -

Introduction To The Preparation Of Low Temperature Chiller’ Operation

1274Why do low temperature chiller need to be ready for operation? We must be very clear that only when we are ready to check the low temperature chiller can we run the equipment better, can we run it more efficiently. Before running the low temperatu...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик