Каковы характеристики системы отопления реактора?

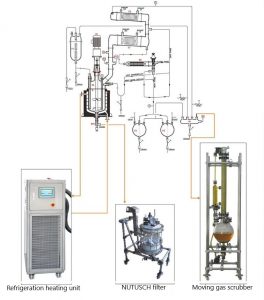

Wuxi Guanya LNEYA reactor heating system The liquid circulation of the whole system is closed, the system has an expansion vessel, the expansion vessel and the liquid circulation are adiabatic, do not participate in the liquid circulation, only the mechanical connection, regardless of the temperature of the liquid circulation is high temperature Or the medium in the low temperature expansion vessel is below 60 degrees. The whole liquid circulation is a closed system. There is no water vapor absorption at low temperature, no oil mist is generated at high temperature, and the heat transfer oil can have a wide working temperature. The same machine, the same heat medium can achieve -95 degrees to 200 degrees. temperature. Cooling capacity 1KW~ 80KW range No mechanical and electronic valves are used in the entire circulation system.

Features of Wuxi Guanya LNEYA reactor heating system:

1. Equipped with heating and cooling integrated container, the heat exchange area is large, the rate of heating and cooling is very fast, and the demand for heat transfer oil is relatively small. Continuous temperature rise and fall can be achieved. The refrigeration heat exchanger adopts a high-force plate heat exchanger, which has high heat exchange efficiency and small floor space. The whole cycle is closed, no oil mist is volatilized at high temperature, the heat transfer oil will not be oxidized and browned; the water vapor in the air will not be absorbed at low temperature; the life of the heat transfer oil is prolonged.

2. Temperature adaptive control, adaptive control system in the process of control technology (such as chemical reaction process), continuously adjust the PID parameters to give the process the best control temperature and response time, this process is through effective multi-directional The rate of temperature, temperature change and temperature change is measured. Features PT100 with correct external and internal circulation temperature probes.

3. With self-diagnosis function, freezer overload protection, high-pressure pressure switch, overload relay, thermal protection device and other safety functions, fully guarantee the safety of use;

4. Use CFC-free and HCFE refrigerants.

5. Precise control of the speed of chemical reactions.

6.Program function series. Nonlinear and linear temperature jump function. Each step of the program includes the control of the external loop program, which is controlled by the PLC controller computer.

7.Automatic diagnosis and system monitoring function series. Through the PLC touch screen controller, the computer implements monitoring and display detailed system information.

Похожие рекомендации

-

-

Как очистить систему управления воздухом?

1848In order to respond to the requirements of the two types of society in the country, environmental protection and conservation have become increasingly important. Therefore, in order to extend the life of the product, it is still necessary to have ...

Посмотреть детали -

Application of Microchannel Reactor Temperature Control System in the Laboratory

1390Application of Microchannel Reactor Temperature Control System

Посмотреть детали -

Форма конфигурации циркуляционной отопительной установки для лаборатории

1529The standard model of the circulating heating unit for LNEYA laboratory is: SUNDI, the temperature range is from room temperature to minus 120 degrees Celsius, and the capacity can be divided into 5L, 10L, 20L, 30L, 40L, 50L, 80L, 100L, larger cap...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик