What are the functions of the reactor temperature control system?

Сайт система контроля температуры реактора is equipped with various reactors for high and low temperature reflection of liquid and solid. The temperature control system of LNEYA reactor adopts fully closed circulation pipeline, which is efficient in operation and less polluted. So, what are the advantages of the reactor temperature control system?

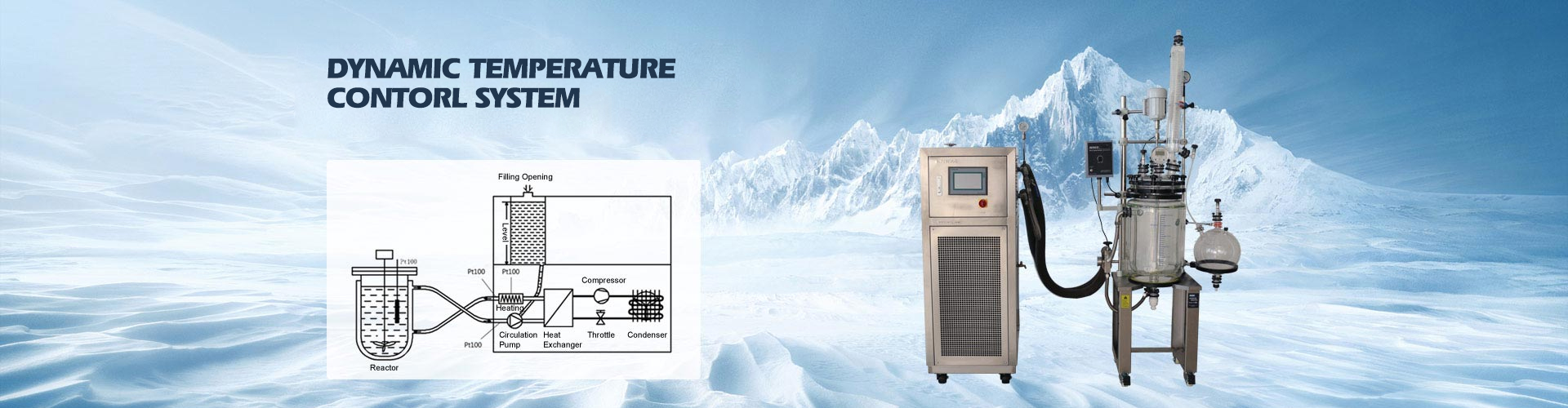

LNEYA applies the technology to the reactor temperature control equipment, which can dynamically display the operating status of each equipment in real time, including real-time data changes of raw material tank weight, feed rate of various materials, valve operation on the equipment and corresponding temperature. The data display, etc., can simulate the flow chart shape, and the image is intuitive and easy to read.

The reactor temperature control system can display the real-time curve and historical data curve of each process parameter, and compare with the set process curve to guide the production process. The displayed historical curve can be saved for more than one year, which is convenient for users to view at any time. With the various process curves and ratios of the memory in the system, it is possible to issue control requirements to the PLC at any time according to the requirements of the production process, so that the production variety and the rapid change of the production process can be completed.

In addition, the reactor temperature control system can print a variety of production and statistical reports, with a very strong management function, the actual weight of each batch and the corresponding temperature, pressure data, etc., to print the data cost Accounting. The LNEYA autoclave automatic control system can perform manual and automatic interference-free switching operations. In order to enhance the performance of the whole system without losing flexibility, the system is equipped with computer operation and can be operated by touch screen, whether manual or not. Automatic or console button operation can be implemented very conveniently.

The reactor temperature control system uses an intelligent control technology to dynamically adjust the temperature by automatically adjusting the multi-parameters of the reactor jacket cooling water and material feed rate, thus allowing various physical processes and The chemical reaction process is more efficiently controlled.

The LNEYA reactor temperature control system uses a complete safety protection device to ensure safety problems in the production process of the reactor temperature control system to a greater extent.

(This article source network, if there is infringement, please contact LNEYA to delete, thank you.)

Похожие рекомендации

-

Разница между большим холодильным и нагревательным циркулятором и испытательной камерой

14691. Для высокотемпературного испытания при особых обстоятельствах высоко- и низкотемпературная испытательная камера может не соответствовать требованиям. Вообще говоря, верхний предел высокой температуры высоко- и низкотемпературной испытательной камеры составляет 200 ℃, а ее ...

Посмотреть детали -

Меры предосторожности при использовании системы контроля температуры при тестировании пластин

1467Меры предосторожности при использовании системы контроля температуры при тестировании пластин

Посмотреть детали -

How to Debug the Expansion Valve of Low Temperature Freezer?

1827The effective operation of low temperature freezer is relevant to the needed refrigerating effect. It is crucial to correct expansion valve if better cooling effect is wanted. So, how to debug the expansion valve of low temperature freezer?During ...

Посмотреть детали -

What causes sediment in the use of the chiller cooler?

1404A chiller is a water-cooled unit that uses water circulation to provide a constant temperature, constant flow and constant pressure cooling water. The LNEYA cold water system has its own working principle, that is, a certain amount of water is inj...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик