Почему для специальных газов, используемых в процессах производства полупроводников, требуются охладители?

If you have any questions, please contact us

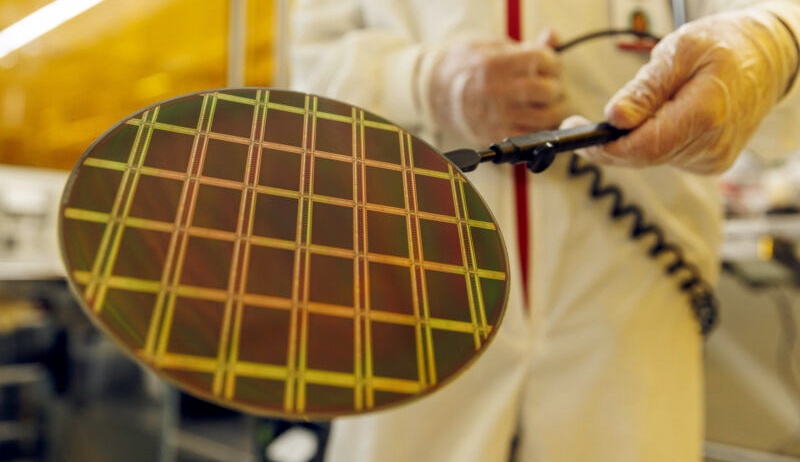

When using special gases in semiconductor manufacturing processes, a chiller is required, mainly due to the following reasons:

- Gas purity control: Special gases are used as raw materials in semiconductor manufacturing, and their purity is crucial to the performance of the final semiconductor device. Some special gases are prone to decomposition or react with impurities such as oxygen and water vapor at high temperatures, reducing their purity. The low-temperature environment provided by the chiller helps maintain the purity of gas during storage and transportation.

- Gas transportation and storage: Some special gases are easy to store in a liquefied state

Transportation, chillers can be used to cool gases to low temperatures, liquefy them, and facilitate storage and metering. Meanwhile, a low-temperature environment is beneficial for slowing down the natural evaporation rate of gases and reducing losses.

3. Process requirements: In semiconductor manufacturing processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), atomic layer deposition (ALD), etc., gas needs to go through a pre-treatment system, including a cooling system, before entering the reaction chamber to maintain gas transport at a specific temperature and prevent gas preheating or premature reaction in the pipeline.

4. Equipment cooling: Semiconductor production equipment generates a large amount of heat during operation, and requires a chiller to provide cooling for its internal gas delivery pipelines, reaction chambers, and other components to ensure that the gas maintains a stable temperature when entering and leaving the chamber. This is crucial for precise process control and product quality.

5. Safety considerations: Some special gases may become unstable or flammable and explosive at high temperatures. Using a chiller can reduce the risk of gas leakage accidents and ensure the safety of the entire process.

Therefore, the chiller is crucial for the storage, treatment, and use of special gases in the semiconductor manufacturing process, and is one of the key equipment to ensure the smooth progress of the semiconductor manufacturing process.

Request a quote

Предоставляем 7*24 бесплатных консультаций и комплексных решений

Похожие рекомендации

-

How to Deal with the Poor Dissipation of Low Temp Chillers

1228Low temp chiller products contribute a lot to various industrial production, and at the same time, help to improve the labor efficiency of industrial production. With the development of China's economy and the improvement of production process req...

Посмотреть детали -

Инструкция по эксплуатации низкотемпературного холодильника с циркуляционным винтовым компрессором

1325Из-за различий в компрессорах производительность низкотемпературных циркуляционных холодильных машин также отличается. Винтовой компрессор отличается от поршневого компрессора, структура которого более сложная. Поэтому, если пользователю необходимо выбрать...

Посмотреть детали -

Efficient method for extracting total cannabinoids using a cryogenic process cooling system

1198Although cannabis plants have been used for medicinal purposes for thousands of years, modern science has identified steroids, flavonoids and more than 100 therapeutically active compounds known as cannabinoids. Due to the significant synergy betw...

Посмотреть детали -

Охладитель для дистилляционного чайника объемом 200 л

799Охладитель для 200-литрового дистилляционного чайника должен одновременно выполнять две основные функции: конденсировать пары метанола и охлаждать материал в процессе реакции. ...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик

Отправить на консультацию

Мы ответим вам в течение 24 часов