How to choose the lubricant for the injection molding machine?

The injection molding machine cooling system lubricating oil needs to pay attention to the type of compressor when selecting. The compressor has three types: piston type, screw type and centrifugal type. The first two kinds of lubricating oil are in direct contact with the compressed refrigerant, and the lubricating oil should be considered. The problem of interaction between the refrigerant and the refrigerant. The lubricating oil used in the centrifugal injection molding machine cooling system is only used to lubricate the rotor bearings, and can also be selected according to the load and the speed.

The injection molding machine cooling system can also select lubricating oil according to the type of refrigerant, and the lubricating oil directly in contact with the refrigerant should consider the mutual influence between the two. For example, a refrigerant such as Freon can be dissolved in mineral oil. Therefore, the viscosity grade of the selected lubricating oil should be one level higher than that of the insoluble refrigerant to prevent lubrication of the injection molding machine cooling system from being diluted. In addition, it should be noted that a small amount of lubricating oil mixed into the refrigerant will not affect the operation of the cooling system of the injection molding machine. The flocculation point of the injection system cooling system oil is a quality indicator for checking whether the lubricating oil mixed in the refrigerant precipitates wax crystals and blocks the refrigeration system.

It is also necessary to pay attention to the evaporation temperature of the refrigerant in the injection molding machine cooling system. The cooling system of the injection molding machine with low evaporation temperature of the refrigerant should use the injection molding machine with low freezing point to cool the system oil, so as to avoid the refrigerant flowing into the cooling system of the injection molding machine. The lubricating oil in the system is condensed on the throttle valve and the evaporator, affecting the cooling efficiency. The cooling system of the injection molding machine using ammonia as the refrigerant should have a freezing point lower than the evaporation temperature and use Freon as the refrigerant. The condensation point of the lubricating oil can be slightly higher than the evaporation temperature.

Lubricating oil is selected according to the working conditions of the injection molding machine cooling system.

Of course, when choosing a lubricant, you need to choose the right lubricant according to the specific working conditions.

Похожие рекомендации

-

Празднуйте Новый год и встречайте Новый год

1322When the bells echo in the clear night sky,When the calendar turns to a new page,We are about to usher in a new year.Thanks for this year's harvestLet us have precious experience on our growthThere is always a reward for sweatThis yearWe sh...

Посмотреть детали -

Инструкции по подготовке к испытаниям микросхем, предназначенных для серии TES-5

969Серия TES-5 для тестирования микросхем используется для тестирования электронных компонентов. Точное определение микросхемы очень важно. Итак, как много вы знаете о подготовке к тестированию серии TES-5 для тестирования микросхем? Прежде чем приступать к испытаниям серии TES-5 для...

Посмотреть детали -

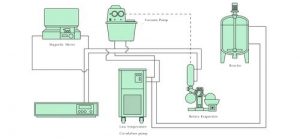

Low-temperature coolant circulation pump used with rotary evaporator

1298The chemical and pharmaceutical fields are the largest end consumer markets for cryogenic coolant circulation pumps. With the increasing demand for low-temperature coolant circulation pumps in this market, the application of cryogenic pumps in the...

Посмотреть детали -

Диапазон регулирования температуры и точность тестера высоких и низких температур

1057Точность контроля температуры теплоносителя тестера высоких и низких температур, используемого для тестирования компонентов, составляет плюс-минус 0,5 ℃, что решает проблему отставания температурного контроля электронных компонентов. Основные преимущества...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик