Reactor Thermal Control Unit and Solutions for Chemicals

Temperature control is a process in which the temperature of a substance or a change in temperature is measured or otherwise detected, and the transfer of thermal energy into or out of the space or substance is adjusted to achieve the desired temperature.

When dealing with pharmaceutical production, maintaining accurate temperature control is critical. Starting with research throughout production, precise temperature control is required at every stage of the process. We fully understand the importance of process cooling, and simple temperature fluctuations (positive and negative) can ruin research or production.

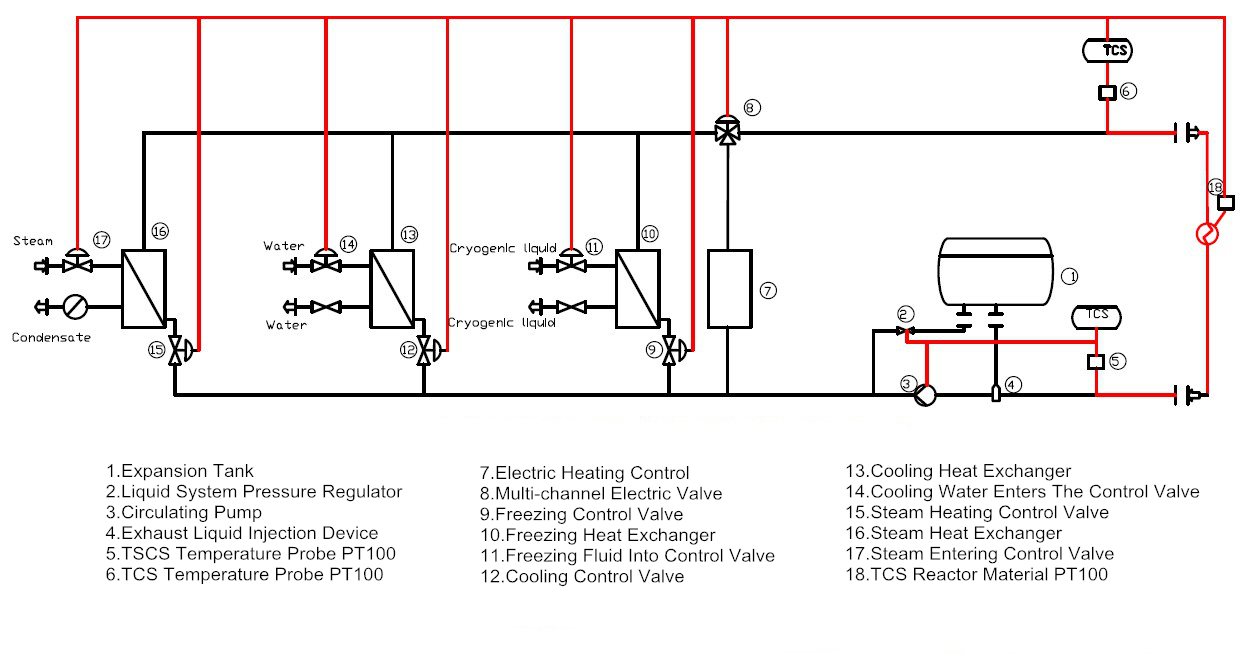

Our TCU can meet all your heating, cooling and temperature control needs for your chemical or pharmaceutical reactor. The LNEYA-TCU temperature control system can utilize existing thermal energy (such as steam, cooling water and ultra-low temperature liquids-the “primary system”) infrastructure integration to achieve dynamic temperature control of the equipment temperature in a single fluid system or a secondary circuit. This only completes the flow of a heat transfer liquid into the jacket of the reaction vessel (rather than directly into the steam, cooling water or cryogenic liquid), and the temperature of the entire reaction process is controlled by calculation.

From -120°C for cryogenic pharmaceutical applications to 300°C for chemical applications, the maximum temperature can be set according to the supplier’s heating or cooling source. The maximum temperature range can be set using a glycol water formula. Through three-point sampling (material temperature point, outlet temperature of temperature control system, inlet temperature of temperature control system), and our own model-free self-building algorithm and general anti-lag cascade algorithm, the problem of large drug delays is solved. Chemical temperature control . Our SR series and ZLF series are completely suitable for low temperature reaction, synthesis, separation process, pilot plant, reactor system, autoclave, combinatorial chemistry, etc.

This will increase product profitability and reactor utilization, and reduce energy and plant operating costs. Our TCU is fully automated and easy to operate. The temperature control accuracy of the product is ± 0.5 ° C, and the cooling power can be provided from 0.5 kW to 1200 kW.

The picture below shows the TCU thermal control unit customized by domestic customers

Похожие рекомендации

-

How to buy a laboratory chiller and maintenance knowledge?

1485Laboratory chillers are products that provide constant temperature cold sources in industry and laboratories. If they cannot provide accurate cooling capacity, it will affect the operation of the equipment. Therefore, the laboratory chiller should...

Посмотреть детали -

LNEYA Холодный и горячий аппарат SUNDI инструкция

2067Температурный диапазон горячей и холодной машины варьируется от -120 °С до 350 °С. Она обладает превосходной производительностью и уникальными характеристиками. Она имеет высокую точность и интеллектуальный контроль температуры. Высокая мощность охлаждения составляет от 0,5 до 1200 кВт. Высокая п...

Посмотреть детали -

What are the conditions for the decarboxylation reaction? How to control the temperature of heating?

1898The decarboxylation of aromatic acids is easier than that of fatty acids. For example, benzoic acid can be decarboxylated by adding a little copper powder as a catalyst in quinoline solution and heating. When a strong electron-withdrawing group i...

Посмотреть детали -

Турнир по бадминтону LNEYA 2020 успешно завершился

1737In order to enrich employees' spare time, enhance cohesion among employees, create a sunny, energetic and passionate working atmosphere, and demonstrate the company's positive, healthy and upward spirit, LNEYA held the third "Guanya Cup" badminton...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик