Description of industrial grade SUNDI heating and cooling temperature control system

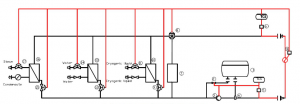

The industrial-grade heating and cooling temperature control system SUNDI series is a device developed and manufactured by LNEYA using its own advantages in the field of cooling, heating and temperature control, and supports customized services in the current technical range and temperature range.

If the industrial kettle heating and cooling temperature control system is used, the temperature can be quickly raised or lowered to reach our set value, and the set value and actual value will be displayed on the panel. The industrial heating and cooling temperature control system heats up very evenly. Generally, the temperature is adjusted using PID self-defined intelligent control, and the temperature control accuracy is 1 ℃, which can better meet the different needs of the product process!

LNEYA’s cooling and heating temperature control system UNDI series can reach 350 ℃, with good thermal stability, dedicated heat transfer oil is not easy to coke and carbon deposit oxidation, combined with the technical experience accumulated in production practice, research and solve the problem in development and design , Manufacturing, installation, operation and repair of theoretical and practical problems in various machinery.

The temperature control of each reactor and reactor requires industrial-grade heating and cooling temperature control systems. The heating system provides accurate temperature control. The SUNDI series uses brand temperature control instruments and uses PID self-tuning intelligent temperature control technology. The control accuracy can reach ± The temperature is around 1 ℃, which can accurately control the use temperature.

The hot oil cooling system can be designed according to user requirements to meet the production process requirements that require rapid cooling after heating. Continuously reduce energy consumption and low operating costs. The heat transfer oil heating system is a liquid-phase closed circuit. The difference between the oil output temperature and the oil return temperature is 20 ℃ -30 ℃, which means that only the temperature difference between 20 ℃ -30 ℃ can reach the operating temperature. It can be customized according to the requirements of different industries, strive to achieve customer-accurate temperature control accuracy, adopt reasonable technical design process, more accurate temperature control, faster heat conduction, high efficiency and energy saving.

Похожие рекомендации

-

Циркулятор охлаждающей воды для тестирования BMS батарейных блоков с жидкостным охлаждением

1567По мере того, как температура воздуха постепенно повышается, использование циркуляторов охлаждающей воды BMS для батарей с жидкостным охлаждением также постепенно достигает своего пика. Циркуляторы охлаждающей воды для BMS-тестов аккумуляторных батарей с жидкостным охлаждением имеют номинальную мощность от...

Посмотреть детали -

Важность управления температурным циклом нагрева и охлаждения при производстве API

2021Китай стал крупнейшим в мире рынком поставок API. Большинство API и промежуточных продуктов, необходимых иностранным производителям, закупаются в нашей стране. Процесс аутсорсинга большинства препаратов, процесс производства...

Посмотреть детали -

What do the LNEYA chiller fault codes mean? What is the solution?

2513Q: What is the fault code of the chiller? Answer: E1 means extremely high indoor temperature alarm, E2 means extremely high temperature alarm, E3 means extremely low temperature alarm, E4 means indoor temperature controller failure, E5 means water...

Посмотреть детали -

Chemical synthesis process control system temperature control system TCU

1787Today, let's talk about our DCS integrated control system (temperature and other control of synthetic process). Scalability: the system is an open system, which provides standard TCP / P data communication interface protocol, interface software an...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик