Structural Characteristics of Industrial Recirculating Chiller

In the chemical reaction, there are strict requirements for the reaction temperature. It is necessary to raise the temperature to an appropriate temperature to carry out the chemical reaction smoothly. After the reaction, the temperature in the reactor must be reduced to room temperature. The existing heating system of the reactor is relatively simple, so the process of reducing the temperature in the reactor to room temperature takes a long time, and the thermal energy can not be used reasonably, resulting in a waste of some resources. Therefore, a temperature control system for rapid heating or cooling is required.

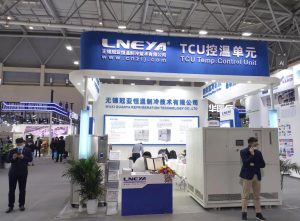

The reactor cooling and heating recirculating chiller is a typical cooling recirculating chiller with heating function. It is suitable for the laboratory and can ensure the repeatability of the experimental results. The operating temperature range is – 45 ℃to 250 ℃. the reactor refrigeration and heating recirculating chiller produced by our company has compact structure, small floor area and environmental protection. It can be placed in the ventilation place of the laboratory or used inside the equipment.

Refrigeration heating recirculating chiller is a temperature controller integrating refrigeration and heating. It is composed of two systems, two computer PC boards, each controlling the corresponding system, and automatically adjusting heating or cooling through heat transfer oil circulation according to process requirements. It consists of pump, heating pipe, cooling heat exchanger, refrigeration system, temperature control system, pipeline and frame. The heat transfer oil flows between the heat medium pipe of the unit and the jacket or coil of the reactor. The circulating pump, heat transfer oil pipe, heating device and cooling device constitute the basic circuit of the heat medium.

Many chemical reactions are accompanied by a large number of endothermic or exothermic phenomena. Temperature is an important process parameter in the production process. Our recirculating chillers provide a variety of modes from small refrigeration power to large refrigeration power, from laboratory to production site, so as to provide continuous and stable process temperature control.

Похожие рекомендации

-

How to solve the alarm signal issued by the chillers of the battery module?

1691The battery module refrigeration and heating machine is mainly in the fields of electronics, metal, aviation, automobile, scientific research, etc. So how to solve the problem when the equipment sends out an alarm signal? The circulation system of...

Посмотреть детали -

-

Buying Tips of Ultra Low Temperature Freezer

1643As for the industrial refrigerating treatment, the ultra low temperature freezer is indispensable. Let me tell you something about it!The ultra low temperature freezer of Wuxi Guanya Refrigeration technology co., Ltd is mainly used in industrial r...

Посмотреть детали -

Описание разработки системы тестирования вафельных микросхем

1548With the development of the semiconductor industry, the wafer chip test machine has also made great progress. How much do you know about the development of the wafer chip test machine? The integrated circuit industry has gradually emerged since th...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик