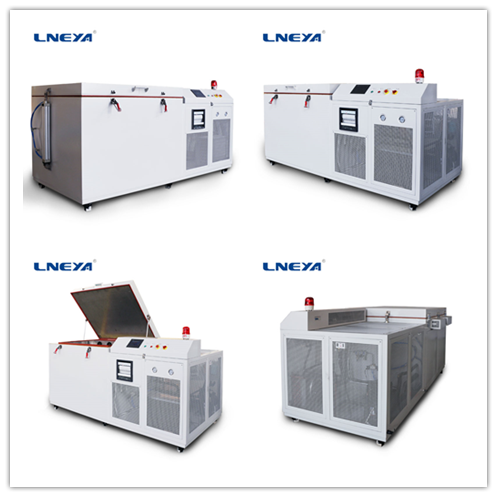

Description of LNEYA industrial ultra-low temperature freezer

LNEYA industrial ultra-low temperature freezer is mainly used in industrial cold treatment to precipitate uniform, fine and dispersed carbides on the metal structure matrix. The appearance of such a carbide will bring about a significant increase in the wear resistance and friction properties of the metal, and the hardness will also increase, and will directly increase the life of the wear member. The ideal product to replace liquid nitrogen.

It can also be used for cold shrinkage of copper sleeves, bearings, etc., and is widely used in precision mechanical assembly. It is used in large equipment (automotive, large engineering machinery, aircraft parts, aerospace equipment parts, military equipment parts, ultra-low temperature test. It can be used for touch screen, display freeze degumming, disassembly.

Different manufacturers have different needs, so most of the cold processing equipment is made according to the requirements. Please provide the following indicators when ordering:

1 maximum load;

2 liner size: length, width, height;

3 Full load cooling to the target value time.

LNEYA industrial ultra-low temperature freezer uses nickel-chromium alloy electric heating heater, the controller itself has 2 protection, plus independent temperature limiter protection. Cooling of the equipment: (25 ° ambient temperature, under no-load conditions, from 0 degrees to -110 degrees for about 1.5 hours); (25 ° ambient temperature, under no-load conditions, from 0 degrees to -140 degrees About 2 hours); the device will have a slightly different cooling rate due to changes in ambient temperature.

The control mode of the device is ASET multi-function controller; 7-inch color touch screen, display setting temperature, measuring temperature and so on. The temperature curve records the temperature, and the U disk data is exported. The format is excel table and the fault record. The circulating air inside the cabinet: 2100m3/h; 2750m3/h; 4500m3/h….. When the door is opened, the internal circulation fan is automatically turned off, and the door opening state is displayed on the touch screen screen.

Compressors for all temperature ranges are international brands: Emerson Copeland compressors, which use single-compressor automatic cascade refrigeration technology.

Похожие рекомендации

-

Simulation analysis and result analysis of battery pack thermal management

1640battery pack thermal management simulation analysis

Посмотреть детали -

Техническое обслуживание системы смазки водоохлаждаемой холодильной установки

1534Среднеразмерный низкотемпературный морозильник, диапазон температур охлаждения от -80 ℃ ~ -30℃, безопасный, надежный, быстрое охлаждение для жидкости, широко используется в нефтехимической, медицинской, фармацевтической, биохимической и сублимированной, военной и других высокотехнологичных отраслях промышленности.

Посмотреть детали -

Меры предосторожности при обслуживании испарителя мощного промышленного холодильника

1744Мощные промышленные холодильники используются для обработки холода в промышленности. Испарители в мощных промышленных холодильниках являются одним из наиболее важных компонентов и одним из факторов, влияющих на эффект охлаждения мощных промышленных ре...

Посмотреть детали -

Как повлияет на батарею запуск автомобиля на топливных элементах в холодном состоянии при низкой температуре?

1697В настоящее время тема автомобилей на топливных элементах в Китае является относительно актуальной. Автомобили на топливных элементах обладают такими преимуществами, как большое рыночное пространство, высокий технологический статус, короткое время гидрирования, большой срок службы батареи и низкий уровень загрязнения. Тем не менее, в настоящее время автомобили на топливных элементах...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик