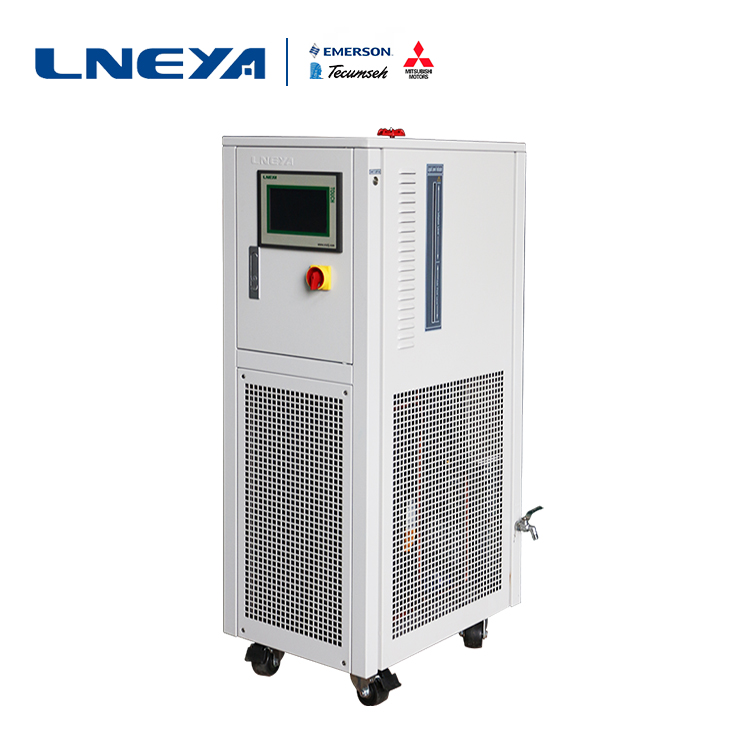

Closed hot and cold cycle machine compressor fault repair process

LNEYA’s closed-type hot and cold cycle machine adopts single-machine self-cascading refrigeration technology, and its compressor also uses the brand compressor, which is more stable in performance. Therefore, it is easy to choose a series of compressors with general performance. malfunction.

If the screw compressor is used in the closed type hot and cold cycle machine, the operation and maintenance process is very simple. Before the screw compressor of the closed type hot and cold cycle machine must be overhauled, if possible, the slide valve is unloaded to the “0” position. , normal shutdown, cut off the power. The compressor can be disassembled by cutting off the piping connected to the compressor and discharging the refrigerant and lubricating oil in the compressor. Be careful to develop good habits when disassembling. Parts of different parts should be placed separately and the necessary assembly marks should be made.

After removing the pipes, couplings and anchor bolts connected to the compressor of the closed type hot and cold cycle machine, the compressor is lifted to the workplace. Remove the suction filter, suction check valve, and remove the energy indicator. Remove the locating pin, remove the suction end cap in parallel, and take out the oil piston and balance piston. Note that when the positioning pin is taken, it can only be pulled out and cannot be pulled out. Be sure to take out the positioning pin first, then remove all the bolts to prevent the weight of the suction end cover from acting on the positioning pin and bend the positioning pin. Remove the shaft cover and remove the shaft seal. Be careful not to touch the moving and stationary rings, remove the positioning pin, remove the exhaust end cap, and remove the bearing gland, lock nut, washer, thrust bearing, adjusting pad, etc. To remove the locknut, use a special special tool and first open the lock tab of the lock washer. Mark them at any time and place them separately. After removing the compressor positioning pin, remove the exhaust end seat and use the special eye bolt to slowly and smoothly remove the active rotor, and do not collide with the body. At this time, the driven rotor rotates accordingly, and the driven rotor is taken out and the spool is taken out.

Wuxi Guanya (LNEYA) closed type hot and cold cycle compressor adopts Hanzhong, Bitzer, Copeland, Danfoss and other brands, and its performance is reliable. It is suitable for refrigeration, chemical and other industries, and has been highly praised by users.

Похожие рекомендации

-

Испытание аккумулятора Работа охладителя Описание температуры испарения

1922In the current new energy vehicle battery test equipment, the use of more batteries to test the chiller evaporation temperature has a certain impact on the equipment, then what is the specific impact? When the battery test chiller heat load increa...

Посмотреть детали -

Советы по выбору бренда для ультранизкотемпературного морозильника

1403Когда речь заходит о сверхнизкотемпературном морозильнике, большинство людей начинают беспокоиться, потому что сверхнизкая температура означает, что технология становится более сложной. По сравнению с другими хладагентами, выбор ультранизкотемпературного морозильника...

Посмотреть детали -

Is the centrifugal pump or the volumetric pump selected in the pharmaceutical laboratory?

1531In the pharmaceutical laboratory, a variety of refrigeration equipment is used more, then as a more common equipment - pumps, mainly centrifugal pumps, volumetric pumps. Then, the user friend should have a better understanding of their performance...

Посмотреть детали -

На что следует обратить внимание при установке системы охлаждения сваи для зарядки постоянным током?

1403pay attention to when installing a DC charging pile cooling system

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик