How to solve the problem of poor cooling performance of the heat transfer oil circulation system?

Some heat-conducting oil circulation systems will not be as good as before after 3 months of use. At this time, it is recommended to contact the professional after-sales department to check the user’s power supply and whether the equipment is normal. The test heat conduction oil circulation system is set to cool operation, and the working pressure is 4.5kg/cm2. Considering that the variable frequency heat transfer oil circulation system uses the electronic expansion valve to throttle, it is not accurate to judge the fault only by the working pressure. Therefore, the outdoor working current is measured again. The measurement finds that the working current is only 10.5A, which is much smaller than the rated value, and the fault is determined as “ Lack of refrigerant.”

Then, first find out the refrigerant leakage part of the heat transfer oil circulation system. Try to open the mechanism heat, use the washing spirit liquid to coat the joints for leak detection, and find that the joint is not tightened, which is the cause of refrigerant leakage. After tightening, check the leak again to make sure the pipeline is intact and then charge the system with refrigerant.

The heat transfer oil circulation system uses the “constant flow charging method”. In order to ensure the accuracy of the refrigerant charge, the exhaust pipe temperature sensor is first suspended. After starting up, use the ammeter to measure the current on the outdoor power line of the heat transfer oil circulation system. As the refrigerant replenishment increases, the current will gradually increase. When the rated current value reaches 12A (the 70-type inverter cabinet is 16A), the refrigeration The dosage of the agent is appropriate. This method is often used during home repairs.

If the heat transfer oil circulation system is overhauled or the leak is too large, and the refrigerant has leaked out in the system for a long time, the refrigerant can be charged by the quantitative method. First, the system is evacuated, and vacuuming or external air evacuation can be used. Then, the system is filled with refrigerant according to the standard. If the external air is emptied, it should be slightly less than the standard amount and in the cold state. These are the reasons why after a few months of use, suddenly become uncooled or poorly cooled.

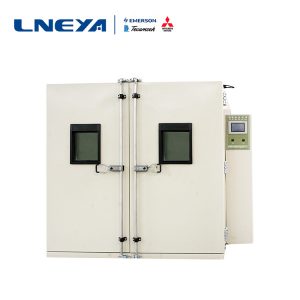

LNEYA provides professional heat transfer oil circulation system, which is mainly engaged in professional brand equipment, with safe and reliable quality. If you need it, please come and purchase it.

Похожие рекомендации

-

Summary – the cause of the failure of the 85 ° C ultra-low temperature refrigerator

1458-85 ° C ultra-low temperature refrigerator in industrial cold treatment, with the development of industry, the scope of use is also wider. However, in the process of use, it will inevitably lead to failure, so how much do you know about common fau...

Посмотреть детали -

Description of the characteristics of the LNEYA walk-in test chamber

1374Wide temperature control range can meet the user's various needs.Unique balanced temperature control method, a stable and balanced heating capacity can be used for high precision and high stable temperature control.The temperature displayed by tou...

Посмотреть детали -

Принцип охлаждения низкотемпературного холодильника

1428Принцип охлаждения так называемого низкотемпературного чиллера заключается в использовании искусственного метода, компрессорного охлаждения, за счет потребления энергии, в циклическом процессе, в процессе которого охлаждающие материалы отводят тепло. Как правило, спе...

Посмотреть детали -

VOCS condensation price and maintenance instructions

1500The performance of VOCS condensing equipment is closely related to the VOCS condensing price. The proper VOCS condensing equipment is definitely superior in performance. What should be paid attention to in the maintenance of VOCS condensing equipm...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик