Преимущества низкотемпературного охлаждающего рециркуляционного чиллера

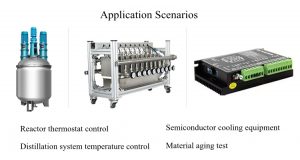

Low temperature cooling recirculating chiller is a kind of refrigeration using compressor, and the circulating pump provides cold source to maintain the temperature range from – 2 5℃ to 30 ℃. The refrigeration recirculating chiller has a space-saving vertical configuration and good heat dissipation effect. It can effectively control the external closed liquid loop when the temperature is far lower than 0 ℃. It is suitable for water, oil or other media of the manufacturer. All recirculating chillers can be connected with other equipment through hoses and used as a constant temperature source.

The high and low pressure of the low-temperature recirculating chillers are 2.5bar and 0.7bar respectively. The air-cooled fully enclosed compressor unit is used for refrigeration, microcomputer intelligent control, automatic opening and delayed closing of the refrigeration system, overheating and current multiple protection devices. It is widely used in petroleum, chemical industry, medicine, life science, metrology, light industry, scientific research and other fields.

Преимущества низкотемпературного охлаждающего рециркуляционного чиллера

1. One of the characteristics of the refrigeration cycle is the large single pressure ratio, but with the increase of the pressure ratio, the efficiency of the screw chiller decreases and the power consumption is large.

2. In order to expand the application range of screw chiller, improve the performance at low temperature and achieve the purpose of energy saving.

3. Taking advantage of the unidirectional operation of suction, compression and exhaust of the screw machine, an intermediate air supplement orifice can be set at a certain position where the rotor starts to compress, so that the single screw refrigerator can operate according to two compression, that is, the screw chiller with economizer.

4. It is usually used when the evaporation temperature is – 25 ℃ ~ 30 ℃. Compared with the original single screw chiller, the refrigeration capacity and refrigeration efficiency are greatly improved, and electric energy can be saved at the same time.

Похожие рекомендации

-

Analysis of the causes of noise generated by the operation of low temperature chillers

1578Noise is common in the operation of industrial equipment. There are many reasons for noise, which may be caused by some environmental problems in the installation. When noise is generated, we must first confirm the cause and whether it is an inter...

Посмотреть детали -

Why does a glass reactor require a circulating chiller and heater?

1280The common glass reaction vessels on the market can be divided into three categories: negative pressure glass reaction vessels, vacuum glass reaction vessels, and high-temperature and high-pressure stirred glass reaction vessels. The g...

Посмотреть детали -

Effect Of Humidity On Laboratory Chillers

1569The high humidity reduces the insulation strength of the electrical equipment of the chiller in the laboratory. The moisture in the air adheres to the surface of the insulating material to form condensation, which reduces the insulation resistance...

Посмотреть детали -

Как решить проблему отказа системы автоматического контроля температуры реактора?

1810The performance of the automatic temperature control system of the reactor is very important. Once you encounter a failure that cannot be started, you must solve it as soon as possible, otherwise the uncontrollable temperature will affect the reac...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик