Что делать, если оборудование камеры для испытания на тепловой удар не достигает заданной температуры

The choice of the manufacturer of the thermal shock test chamber is related to the quality of the thermal shock test chamber. Once the quality is set, the temperature setting of the equipment will not be closed. What should I do if I encounter the temperature setting problem?

The temperature set by the thermal shock test chamber is not up to the possibility that the heat exchange humidification tube is broken. You can either repair the factory or replace the new thermal shock test chamber directly. In the high temperature test, if the temperature does not change. When testing the temperature value, the electrical system can be inspected to eliminate the fault one by one, or the temperature probe may be broken, causing the device to not work when the water temperature is lower than the set standard temperature or 37 degrees.

The temperature and temperature of the thermal shock test chamber is too long or the heating tube is aging and damaged. When the actual water temperature is far below 37 degrees, the equipment has not worked, or the work is not working. If the temperature rises directly to cause over-temperature protection, the controller fails and the control instrument must be replaced. If the temperature is too high, you need to set the PID setting parameters first.

If the temperature rises very slowly, it is necessary to check the air circulation system to see if the regulating baffle of the air circulation is normally turned on. If the temperature of the thermal shock test box rises very quickly, check whether the motor of the air circulation is running normally. Because there is a time limit for use, so the running time is too long, it is inevitable that there will be some kinds of various faults, usually pay attention to regular maintenance and maintenance, generally can be largely avoided. If you encounter a large technical problem, you should seek solutions in time with the manufacturer.

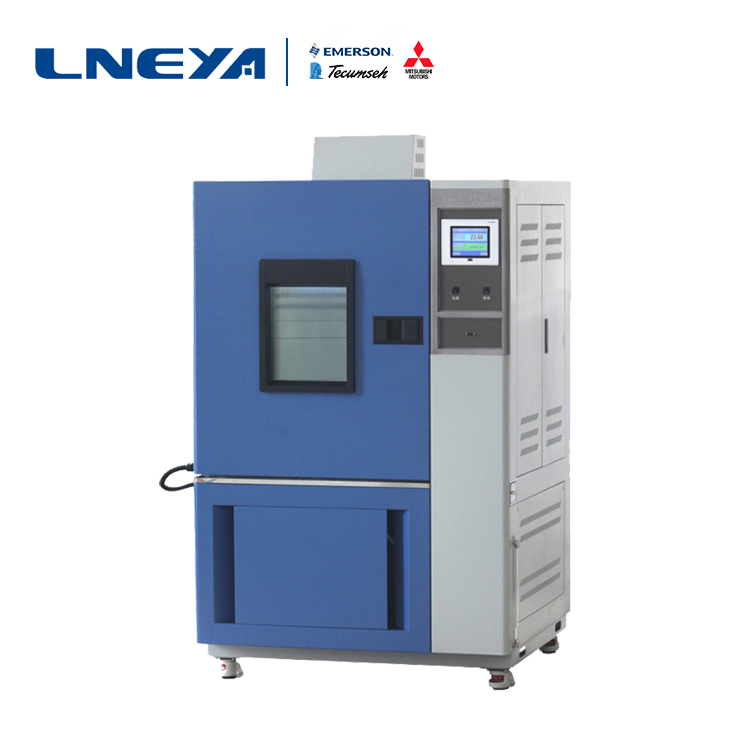

LNEYA thermal shock test box manufacturer is a professional hot and cold impact test box manufacturer integrating R&D, production and sales. It has more than ten years of experience in refrigeration and heating equipment production, and has reached cooperation with many domestic enterprises.

Похожие рекомендации

-

Контроль температуры при испытании батареи нового энергетического транспортного средства

1160В связи с непрерывной реализацией политики энергосбережения и сокращения выбросов, развитие новых энергетических батарей также постоянно стимулируется, а системы жидкостного охлаждения стали неизбежной тенденцией для новых энергетических транспортных средств. В связи с этим в последнее время все большее распространение получает...

Посмотреть детали -

Development prospect of temp measurement and temperature control device for microfluidic chip system

1384With the continuous development of China's science and technology, there has been great progress in the field of integrated circuits and chips. The temperature measurement and temperature control devices in the LNEYA microfluidic chip system have ...

Посмотреть детали -

Взрывозащищенный ультранизкотемпературный холодильник с инструкцией по внутренней утечке

12921. Sound leak detection method: First, the refrigeration pipeline of the explosion-proof ultra-low temperature refrigerator is filled with nitrogen. Then use a stethoscope to check the interior. When you hear a leak in a certain area, mark it. Car...

Посмотреть детали -

Требуют ли моторные испытания новых энергетических транспортных средств установки охладителя или нагревателя?

806Для испытания двигателя нового энергетического транспортного средства требуется как охладитель, так и нагреватель, поскольку испытания двигателя охватывают широкий диапазон температурных условий для обеспечения производительности и стабильности работы двигателя в различных условиях эксплуатации. Охладитель: В ...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик