Как влияет небольшой чиллер с водяным охлаждением на промышленное производство?

Небольшой чиллер с водяным охлаждением используется в самых разных областях, например, в пищевой и фармацевтической промышленности. В некоторых областях промышленности часто требуются небольшие чиллеры с водяным охлаждением. Применение ...

The application of small water cooled chillers in industrial production has the following aspects:

First, the water cooled chiller chemical industry. Small water cooled chiller is mainly used for cooling of chemical reactors (chemical heat exchangers), timely taking away the huge heat generated by chemical reactions to achieve lowing the temperature (cooling) to improve product quality.

Second, water cooled chiller plastic products, plastic containers, food packaging film, medical packaging film manufacturing industries, etc. In the injection molding process of plastic products (television, computers, washing machines, mobile phones, refrigerators, air conditioners, plastic toys, automotive plastic parts) Whether the cooling can be timely and effectively cooled (cooling) will directly affect the appearance and appearance of the product, thereby affecting production efficiency, affecting production costs and corporate profits.

Third, the cooling of the water-cooled chiller plating solution, hydraulic oil and machine tool cutting tool coolant. In the electroplating production, the plating solution generates heat in the electroplating reaction, so that the temperature of the plating solution is gradually increased, when the temperature of the plating solution is high. When the temperature of the plating solution is higher than the requirements of the process, the firmness, uniformity, flatness and surface finish of the surface plating of the produced electroplated products will also be affected. The choice of a small water cooled chiller provides the freezing of electronic components in the production process to maintain or cool the components at a specific temperature, the performance parameters of the electronic components can be controlled in the design state. Using water to cool and maintain the constant temperature of the plating solution will greatly improve the electroplating production process and production efficiency. The cooling of the coolant of the machine, and the control of the blade edge temperature will directly affect the tool life and product quality.

Похожие рекомендации

-

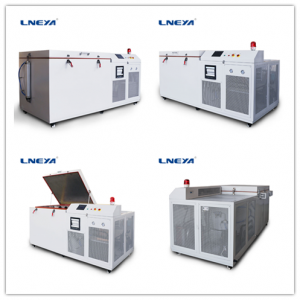

Анализ причин отказа от охлаждения криогенного холодильного оборудования

1095Ультранизкотемпературное холодильное оборудование в основном используется в промышленной обработке холода. В отличие от некоторых производителей ультранизкотемпературного холодильного оборудования, в ультранизкотемпературном холодильном оборудовании LNEYA используются экологически безопасные...

Посмотреть детали -

Explosion-proof high and low temperature integrated machine advantage

1185Explosion-proof high and low temperature integrated machines are used in the current pharmaceutical and chemical industry. The heat transfer medium of the entire circulation system is a fully closed cycle, the circulation system has a liquid expan...

Посмотреть детали -

Description of the power-on tripping of the high-power refrigerator

935Wuxi Guanya LNEYA high-power refrigerator is equipped with brand accessories. The refrigeration performance of the whole high-power refrigerator is relatively stable. Once the power-on trip occurs, it needs to be processed in time to avoid affecti...

Посмотреть детали -

Изменения в методах контроля температуры при испытаниях полупроводников

1099По мере распространения полупроводниковых приборов на новые области, такие как автомобильная электроника, к их характеристикам предъявляются все более жесткие требования. Пример: Устройства должны работать при очень низких температурах (около -40°C). Для определения...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик