Low-temperature coolant circulation pump used with rotary evaporator

The chemical and pharmaceutical fields are the largest end consumer markets for cryogenic coolant circulation pumps. With the increasing demand for low-temperature coolant circulation pumps in this market, the application of cryogenic pumps in the chemical industry is becoming more mature. As a laboratory instrument, cryogenic coolant circulation pumps are indispensable to the laboratory field. It plays an important role in chemical, pharmaceutical and chemical research.

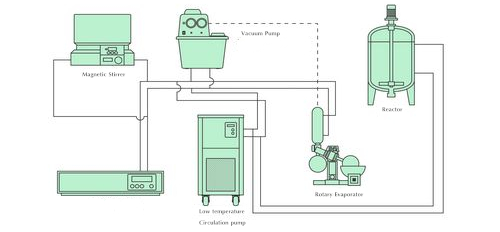

The low-temperature coolant circulation pump can directly cool test tubes, reaction flasks, etc. to carry out chemical reactions at low temperatures, and carry out low-temperature storage of chemicals and biological products. It can also be used in conjunction with rotary evaporators, vacuum freeze-drying boxes, circulating water-type multi-purpose vacuum pumps, etc.

One low temperature coolant circulation pump with two rotary evaporation laboratory cases Note points:

When in use, the actual temperature should not be lower than the minimum temperature. If water is used as the circulating solution, the water inlet pipe cannot be higher than 60 degrees Celsius, but when using absolute ethanol, the water inlet can not be higher than 10 degrees Celsius.

Lneya low-temperature coolant circulation pump adopts international brand compressor, which has small volume and high efficiency. Single compressor can achieve -152°C temperature control. The shell material is cold-rolled steel plate, and the circulating pump with pressure ≤6bar can be customized to make the liquid storage larger capacity according to the needs. Exclusive self-cascade supercooling refrigeration technology, in order to save water resources, can use ethylene glycol-water mixture for circulating refrigeration, strict circulation pipeline design, prevent circulating water pollution, extend the circulating water use time; -125 ° C ~-20 °C Wide temperature range; adjustment unit 0.1 degree. Ambient temperature monitoring function is provided to prevent damage to the system when the ambient temperature is too high.

Похожие рекомендации

-

Зачем механическим заводам нужны чиллеры?

853Существует множество причин, по которым механические заводы нуждаются в чиллерах, и чиллеры играют очень важную роль в процессе механической обработки, что позволяет повысить эффективность производства, обеспечить стабильную работу оборудования и продлить срок его службы.

Посмотреть детали -

Миниатюрный реакционный чайник высокого давления холодильная система управления температурой нагрева

1017Миниатюрный реакционный чайник высокого давления с системой контроля температуры нагрева и охлаждения состоит из блока подачи газа, блока подачи жидкости, блока реакции и блока сбора. Сырьевой газ и сырьевая жидкость смешиваются и пр...

Посмотреть детали -

Solution to the inability to cool down the industrial high and low temperature recirculating chiller

1182When the high and low temperaturerecirculation chiller system is in use, what is the general cause if the hightemperature cannot be reduced? How should we deal with such failures?First, let’s analyze theprinciple and method of cooling. The circ...

Посмотреть детали -

CIPM China [C-48-2] welcomes new and old customers!

1320The 58th (Fall 2019) National Pharmaceutical Machinery & ChinaInternational Pharmaceutical Machinery Expo will be held at the Chongqing International Expo Center from November 5th to November 7th, 2019. It is recognized by the industry as prof...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик

![CIPM China [C-48-2] welcomes new and old custom... CIPM China [C-48-2] welcomes new and old custom...](https://www.lneya.com/wp-content/uploads/2023/05/2-5-300x125.jpg)