What should I do if there is noise from industrial cooling and heating chillers?

The industrial cooling and heating temperature control equipment adopts a PID algorithm temperature control system to accurately adjust the temperature based on the detected temperature and the set temperature value, improving the drawbacks of traditional manual control of the reaction kettle.

1. The industrial cooling and heating temperature control equipment, the chiller circulating pump, converts electrical energy into mechanical energy to promote the liquid phase circulation of the heat transfer oil, and transfers heat to the reaction kettle. The heat transfer oil exchanges with the materials in the reaction kettle and then returns to the oil heater, where it is heated again under the pressure of the pump and enters the next cycle. Through repeated cycles, heat is transferred and transported, heated and cooled, or the temperature of the reactor is maintained to meet the temperature requirements required by the production process.

2. When high noise occurs during the operation of the industrial cooling and heating temperature control equipment, the chiller needs to be inspected and promptly addressed if any problems are found. The internal components of the industrial grade cold and hot temperature control thermostat are excessively worn, such as the wear and tear of the cylinder body and valve plate of the plunger pump, as well as the wear and tear of the matching parts between the plunger and the plug hole, causing serious internal leakage in the pump. When the pump outputs high-pressure and low flow oil, flow pulsation will occur, causing high noise.

3. The pump valve plate is also one of the important components that can easily cause noise. Industrial cooling, heating, and temperature control equipment. During use, the water chiller may shorten the unloading groove and change the unloading position due to surface wear or oil sludge deposition at the opening of the unloading groove, resulting in oil trapping and higher noise.

4. When air is mixed into the cold water oil of industrial cooling and heating temperature control equipment, it is easy to form cavitation phenomenon in its high-pressure zone, which spreads in the form of pressure waves, causing oil oscillation and causing cavitation noise in the system.

Похожие рекомендации

-

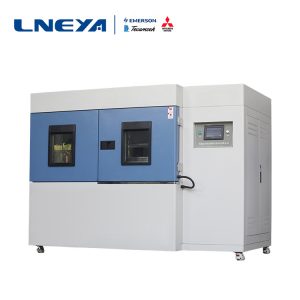

Рейтинговый список высоко- и низкотемпературных испытательных камер с попеременным охлаждением и нагревом

878When choosing the high and low temperature cooling heating alternating test chamber, the enterprise users must have a certain understanding of the ranking list of the high and low temperature cooling heating alternating test chambers on the market...

Посмотреть детали -

Treatment of insufficient exhaust gas in high and low temperature impact test chamber compressor

1222The efficiency of the high and low temperature impact test chamber during use is very important. If there is a shortage of high compressor exhaust, we need our LNEYA technicians to solve it in time. So, how to solve it better? The high and low tem...

Посмотреть детали -

API exhibition LNEYA is brilliant

1251On October 14, 2020, the 85th China International Pharmaceutical Raw Materials/Intermediates/Packaging/Equipment Fair (API China for short) was grandly opened at Nanjing International Expo Center. The exhibition site was bustling and popular. LNEY...

Посмотреть детали -

Каковы последствия отключения питания для криогенного холодильного шкафа с жидким азотом?

941Различные отрасли промышленности предъявляют разные температурные требования к криогенным криостатам. Конечно, существует множество типов криогенных криостатов. Методы охлаждения, используемые в разных отраслях, отличаются. LNEYA использует компрессорное охлаждение...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик