HIGHLY TEMPERATURE CONTROL SYSTEMS

Серия преобразователей частоты SUNDI Z

-80℃~250℃- Мощность охлаждения0.4kW~60kW

- Мощность нагрева3.5kW~60kW

- ХладагентR404A/R507C/R508B

- Вес115KG~300KG

Air-cooling & Water-cooling

DETAIL ADVANTAGE,STRIVING FOR EXCELLENCE

Детали конфигурации

| Модель | SUNDIZ4-3 | SUNDIZ4-5 | SUNDIZ4-10 | SUNDIZ4-15W | SUNDIZ4-20W | SUNDIZ4-30W | |

| SUNDIZ4-3W | SUNDIZ4-5W | SUNDIZ4-10W | |||||

| Диапазон температур | -45℃~250℃ | ||||||

| Мощность нагрева | 5,5 кВт | 7,5 кВт | 15 кВт | 25 кВт | 38 кВт | 60 кВт | |

| Холодопроизводительность кВт | 250℃ | 5,5 кВт | 7,5 кВт | 15 кВт | 25 кВт | 38 кВт | 60 кВт |

| 20℃ | 5,5 кВт | 7,5 кВт | 15 кВт | 25 кВт | 38 кВт | 60 кВт | |

| -15℃ | 2,3 кВт | 3,6 кВт | 7,5 кВт | 11 кВт | 15 кВт | 33 кВт | |

| -35℃ | 0,9 кВт | 1,5 кВт | 3,3 кВт | 5 кВт | 6,5 кВт | 10 кВт | |

| Средняя точность контроля температуры | ±0.1℃ | ±0.1℃ | ±0.1℃ | ±0.1℃ | ±0.1℃ | ±0.1℃ | |

| Точность контроля температуры процесса | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | |

| Расход насоса Давление макс | 50 л/мин | 50 л/мин | 100 л/мин | 150 л/мин | 250 л/мин | 400 л/мин | |

| 2бар | 2бар | 2бар | 2,5 бар | 2,5 бар | 2,5 бар | ||

| Хладагент | R-404A / R507C 可选配R448 | ||||||

| Размер интерфейса | G3/4 | G3/4 | G1 | DN32 PN10 | DN40 PN10 | DN50 PN10 | |

| Модель | SUNDIZ8-3W | SUNDIZ8-4W | SUNDIZ8-6W | SUNDIZ8-10W | SUNDIZ8-15W | |

| Диапазон температур | -80℃~+250℃ | |||||

| Мощность нагрева кВт | 3.5 | 5.5 | 7.5 | 10 | 15 | |

| Cooling capacity kW @ | 250℃ | 3.5 | 5.5 | 7.5 | 15 | 20 |

| 20℃ | 3.5 | 5.5 | 7.5 | 15 | 20 | |

| -60℃ | 1.3 | 1.8 | 3 | 5.5 | 8 | |

| -75℃ | 0.4 | 0.6 | 1 | 1.8 | 2.7 | |

| Medium temperature control accuracy | ±0.1℃ | ±0.1℃ | ±0.1℃ | ±0.1℃ | ±0.1℃ | |

| Process temperature control accuracy | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | |

| Pump flow & pressure max |

35 л/мин | 50 л/мин | 100 л/мин | 150 л/мин | 250 л/мин | |

| 2бар | 2бар | 2бар | 2,5 бар | 2,5 бар | ||

| Хладагент | Primary R-404A + Secondary R508B | |||||

| Размер интерфейса | G3/4 | G3/4 | G1 | DN32 PN10 | DN40 PN10 | |

| Электропитание | 380V 50HZ / 460V 60HZ | |||||

| Индикация давления в системе | Давление в холодильной системе и системе циркуляции определяется датчиками давления и отображается на сенсорном экране | |||||

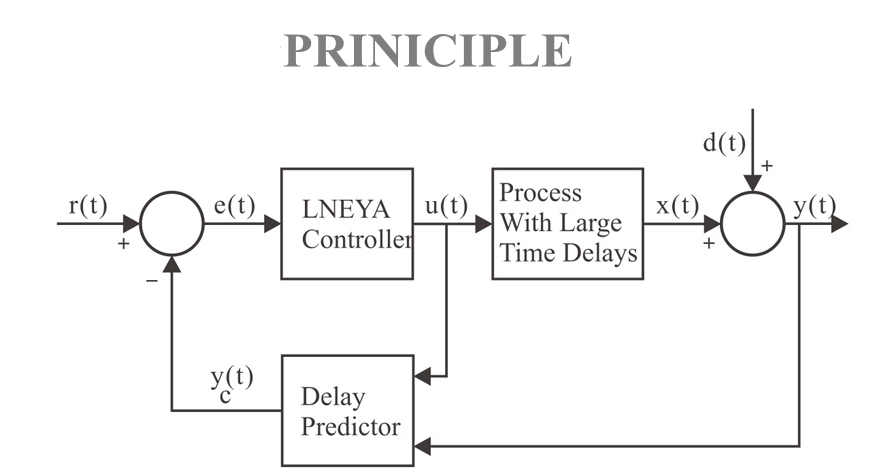

| Контроллер | Siemens S7-1200PLC, fuzzy PID control algorithm, with process dynamic control algorithm | |||||

| Контроль температуры | Режим регулирования температуры теплоносителя на выходе | |||||

| External temperature sensor: (PT100 or 4-20mA or communication setting) Control mode (process dynamic control algorithm) |

||||||

| Программируемый | 25 programs can be knitted, each program can be edited with 85 steps | |||||

| Протокол связи | Ethernet interface TCP/IP protocol, RS485 interface MODBUS protocol | |||||

| Internal temperature feedback | Equipment heat transfer medium outlet temperature, medium inlet temperature, refrigeration system condensation temperature, ambient temperature, compressor suction temperature, cooling water temperature (for water cooling equipment) | |||||

| External temperature feedback | PT100 or 4~20mA or communication setting | |||||

| Cascade control | Разница температур между температурой на выходе и внешним датчиком температуры может быть установлена и контролироваться; | |||||

| Temperature difference control function | The temperature difference between the equipment inlet temperature and the outlet temperature can be set and controlled (to protect system safety) | |||||

| Закрытая система циркуляции | The entire system is a fully enclosed system. There will be no oil mist at high temperatures and no absorption of moisture in the air at low temperatures. The system will not increase pressure due to high temperatures during operation, and will automatically replenish heat transfer media at low temperatures. | |||||

| Отопление | Refers to the maximum heating output power of the system (depending on the model) | |||||

| Нагреватель имеет тройную защиту и независимый ограничитель температуры для обеспечения безопасности системы отопления; | ||||||

| Use a voltage regulator to control the heating output and reduce the heater output current in process temperature control | ||||||

| Охлаждение | It refers to the ability to take away heat at different temperatures (under ideal conditions). The actual working conditions need to consider the heat dissipation of the environment. Please enlarge it appropriately and take insulation measures. | |||||

| External circulation pump flow & pressure | Марка магнитный привод переменной частоты насос | |||||

| compressor | Emerson, Mitsubishi and other inverter compressors | |||||

| Частотный преобразователь | ABB and other well-known brands | |||||

| Испаритель | 316L plate heat exchanger | |||||

| Аксессуары для холодильного оборудования | Danfoss/Emerson accessories (drying filter, oil separator, high and low pressure protector, expansion valve) | |||||

| Панель управления | 7-дюймовый цветной сенсорный экран, отображение кривой температуры\EXCEL экспорт данных | |||||

| Защита безопасности | It has self-diagnosis function; phase sequence failure protector, refrigerator overload protection, overload relay, thermal protection device and other safety protection functions. | |||||

| Хладагент | R-404A / R507C Опционально R448 | |||||

| Конденсатор с водяным охлаждением | Standard plate heat exchanger | |||||

| Casing material | Cold rolled steel plate spraying (standard color RaL7035) | |||||

Ultra high temperature cooling technology can directly cool from a high temperature of 300℃[because only the heat transfer medium in the expansion chamber contacts with oxygen in the air (and the temperature of the expansion tank is between normal temperature and 60℃), which can reduce the risk of heat transfer medium being oxidized and absorbing water in the air. At high temperature, no heat conducting medium evaporates, and continuous temperature control of – 80℃ ~ 190℃, – 70℃ ~ 220℃, – 88℃ ~ 170℃, – 55℃ ~ 250℃ and – 30℃ ~ 300℃ can be realized without pressurization.

FLUID CIRCULATION CLOSED TEMPERATURE CONTROL

The fully enclosed pipeline design and high-efficiency plate heat exchanger reduce the demand for thermal fluid while improving the system’s heat utilization rate and achieving rapid temperature rise and fall. The thermal medium is in a closed system with an expansion container. The thermal medium in the expansion container does not participate in the circulation. Regardless of high or low temperatures, the expansion tank temperature is kept at room temperature to 60°C, effectively reducing the risk of the thermal medium absorbing moisture and volatilizing during operation.

WIDE RANGE OF APPLICATION INDUSTRY SERVICES

Применение: Различные реакторы (микроканальные, стеклянные, реакторы с рубашкой и т.д.), дистилляционные или экстракционные системы, лаборатории, университеты, научно-исследовательские институты, аэрокосмическая, автомобильная промышленность, испытания полупроводников и электрооборудования, химическая, фармацевтическая, нефтехимическая, биохимическая, медицинская, больница, научно-исследовательская мастерская, аэрокосмическая, биологическая и другие отрасли.

APPEARANCE DETAILS OUALITY CONTROL

Вас также могут заинтересовать эти продукты

SUNDI -10℃~150℃

SUNDI -10℃~150℃

Fully enclosed system, single medium completes refrigeration and heating -120~350℃ ±0.5℃ AC 380V 50HZ 8kW max Ultra high temperature cooling technology can directly cool from a hi…

SUNDI -80℃~250℃

SUNDI -80℃~250℃

● Working temperatures from -120°C to +350°C ● Previously unachievable performance ●Intelligent temperature control ● Maximum process stability and reproducibility ● Adop plate heat exchager, Pipeline heating, the fastest he…

SUNDI-320/320W

SUNDI-320/320W

Fully enclosed system, single medium completes refrigeration and heating -120~350℃ ±0.5℃ Ultra-high Temperature Cooling Technology Can Directly Cool Down From 300℃ High Temperature. Bec…

SUNDI -25℃~200℃

SUNDI -25℃~200℃

Fully enclosed system, single medium completes refrigeration and heating -120~350℃ ±0.5℃ ● Working temperatures from -120°C to +350°C ● Previously unachievable performance ●Intelligent temperature control…

SUNDI -45℃~250℃

SUNDI -45℃~250℃

● Working temperatures from -120°C to +350°C ● Previously unachievable performance ●Intelligent temperature control ● Maximum process stability and reproducibility ● Adop plate heat exchager, Pipeline heating, the fastest heat…

SUNDI -60℃~250℃

SUNDI -60℃~250℃

Ultra high temperature cooling technology can directly cool from a high temperature of 300℃[because only the heat transfer medium in the expansion chamber contacts with ox…

SUNDI -80℃~250℃

SUNDI -80℃~250℃

● Working temperatures from -120°C to +350°C● Previously unachievable performance●Intelligent temperature control● Maximum process stability and reproducibility● Adop plate heat exchager, Pipeline heating, the fastest heating…

SUNDI -90℃~250℃

SUNDI -90℃~250℃

● Working temperatures from -120°C to +350°C ● Previously unachievable performance ●Intelligent temperature control ● Maximum process stability and reproducibility ● Adop plate heat exchager, Pipeline heating, the fastest heat…

SUNDI -100℃~100℃

SUNDI -100℃~100℃

● Working temperatures from -120°C to +350°C ● Previously unachievable performance ●Intelligent temperature control ● Maximum process stability and reproducibility ● Adop plate heat exchager, Pipeline heating, the fastest h…

loading…

已经是到最后一篇内容了!

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик