Why is there air in the reactor temperature control system?

The impurity gas in the reactor temperature control system is to increase the condensing pressure of the refrigeration system, thereby increasing the condensing temperature, increasing the exhaust temperature of the compressor, increasing the power consumption, reducing the cooling efficiency, and possibly the exhaust gas temperature is too high. The carbonization of the lubricating oil affects the lubrication effect, and in severe cases, the refrigeration compressor motor is burnt.

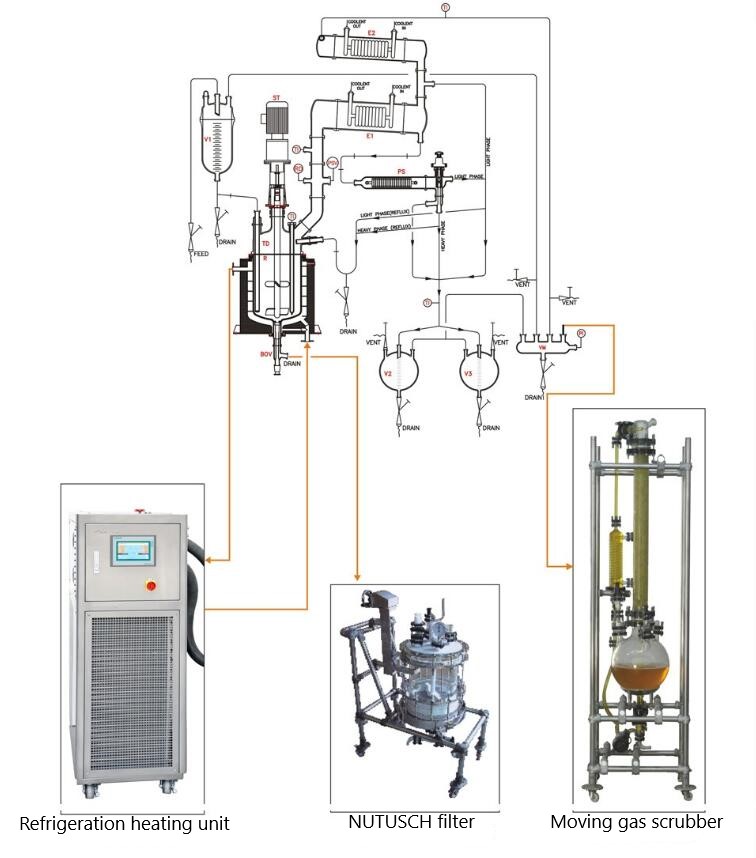

The gas generated in the reactor temperature control system may be leaking air. It may be when the refrigerant is filled or lubricated, the outside air is taken into the air, or the temperature of the reactor temperature control system is not tight enough to cause air to enter. Inside the system. In addition, gas is generated due to decomposition of the refrigerant oil, impure refrigerant, and corrosion of the metal material. Of course, Wuxi Guanya uses a fully enclosed circulation system on the reactor temperature control system to prevent this air from entering the reactor temperature control system.

In general, the gas in the reactor temperature control system is expressed in the reactor temperature control system compressor exhaust pressure and exhaust gas temperature rise, the pressure gauge pointer on the condenser (or reservoir) violently swings, the compressor The cylinder hair is hot, the condenser shell is very hot; the surface temperature of the evaporator temperature control system is unevenly frosted. When there is a large amount of gas in the reactor temperature control system, the ambient temperature cannot be lowered due to the decrease of the cooling capacity of the reactor. The machine runs for a long time, and even the high-pressure relay operates to stop the compressor.

If the reactor temperature control system has these gases, the pressure of the refrigeration system can be measured by a pressure gauge to compare with the saturation pressure at that ambient temperature. If the measured pressure is greater than the saturation pressure at ambient temperature, the system contains gas.

If the above-mentioned gases are found in the reactor temperature control system, it is necessary to eliminate these gases in time and solve the faults in time.

Похожие рекомендации

-

Minimum 40 degree refrigerator use precautions

1716The temperature of the lower 40 degree refrigerator is indoor temperature: 5-32 °C, relative humidity 80%/22 °C, the distance from the ground > 10cm, the altitude below 2000m, the safe environment guarantees a smoother operation of the lower 40...

Посмотреть детали -

Каков контроль температуры в реакторе?

1856Система охлаждения реактора является одним из распространенных видов оборудования в химической промышленности. Она может не только нагревать, но и охлаждать, чтобы удовлетворить потребности в нагреве и охлаждении в процессе реакции. Обычно существует три способа контроля температуры...

Посмотреть детали -

Необходимость испытательной системы для батарей электромобилей новой энергии

1415The battery performance of new energy vehicles directly determines the experience of new energy vehicle end users. The electric vehicle battery test system needs to test the performance reliability of new energy vehicle batteries. With the develop...

Посмотреть детали -

Explosion-proof cryogenic refrigeration unit instructions

1582Explosion-proof cryogenic refrigeration units are used in many industries. When users use them, they need to understand their corresponding usage instructions to avoid improper operation and more efficient operation. The energy consumption of the ...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик