Что делать, если оборудование камеры для испытания на тепловой удар не достигает заданной температуры

The choice of the manufacturer of the thermal shock test chamber is related to the quality of the thermal shock test chamber. Once the quality is set, the temperature setting of the equipment will not be closed. What should I do if I encounter the temperature setting problem?

The temperature set by the thermal shock test chamber is not up to the possibility that the heat exchange humidification tube is broken. You can either repair the factory or replace the new thermal shock test chamber directly. In the high temperature test, if the temperature does not change. When testing the temperature value, the electrical system can be inspected to eliminate the fault one by one, or the temperature probe may be broken, causing the device to not work when the water temperature is lower than the set standard temperature or 37 degrees.

The temperature and temperature of the thermal shock test chamber is too long or the heating tube is aging and damaged. When the actual water temperature is far below 37 degrees, the equipment has not worked, or the work is not working. If the temperature rises directly to cause over-temperature protection, the controller fails and the control instrument must be replaced. If the temperature is too high, you need to set the PID setting parameters first.

If the temperature rises very slowly, it is necessary to check the air circulation system to see if the regulating baffle of the air circulation is normally turned on. If the temperature of the thermal shock test box rises very quickly, check whether the motor of the air circulation is running normally. Because there is a time limit for use, so the running time is too long, it is inevitable that there will be some kinds of various faults, usually pay attention to regular maintenance and maintenance, generally can be largely avoided. If you encounter a large technical problem, you should seek solutions in time with the manufacturer.

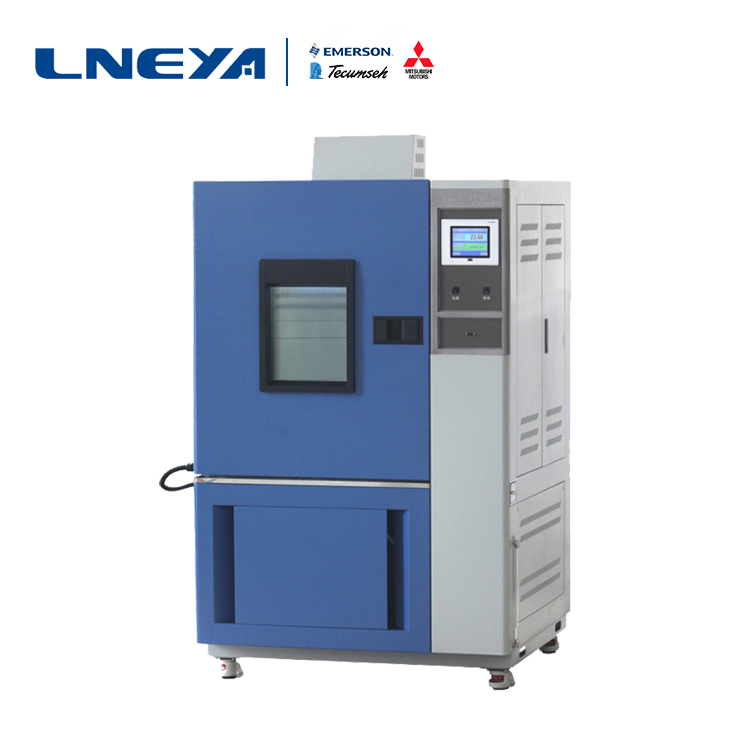

LNEYA thermal shock test box manufacturer is a professional hot and cold impact test box manufacturer integrating R&D, production and sales. It has more than ten years of experience in refrigeration and heating equipment production, and has reached cooperation with many domestic enterprises.

Похожие рекомендации

-

Анализ работы и промышленного применения чиллера

1684Although there are many different types of chillers, most use the same cooling principle. An important part of the process is the coolant or refrigerant, which holds more heat than water and helps maintain an efficient cooling process. Heat is rem...

Посмотреть детали -

Описание работы компрессора высоко- и низкотемпературной цикловой машины

1892Важность работы компрессоров машин с высоко- и низкотемпературным циклом должна быть известна каждому, поэтому компания LNEYA напоминает пользователям, что необходимо понимать здравый смысл работы компрессора. Высокотемпературный и низкотемпературный...

Посмотреть детали -

Types of Environmental Tests

1769The environmental chamber is one of the many types of experiments used in scientific research, product development, production and evaluation. The fundamental difference between environmental tests and other tests is that there are specific requir...

Посмотреть детали -

Application field of LNEYA water heater circulator

1862Hot water circulation, this is a very good water heater device and is now used in many places. By using a hot water circulator, people can solve the problem of domestic hot water use. Today we will introduce some applications of hot water circulat...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик