О инструкциях по выбору хладагента для высоко- и низкотемпературных цикловых машин

In the operation of high and low temperature cycle machines, the presence of refrigerant is essential, and the environmentally friendly mixed refrigerant used by LNEYA is better in terms of performance.

The high and low temperature cycle machine has a higher critical temperature and can undergo a phase change at normal temperature or normal low temperature, which is a basic requirement for the refrigerant in the steam high and low temperature cycle machine. High and low temperature cycle refrigerant suitable for saturated vapor pressure. Do not lower the evaporation pressure below atmospheric pressure to prevent air from leaking into the refrigeration system. The condensing pressure should not be too high to avoid excessive increase of high and low temperature cycle machines and equipment. At the same time, the ratio of the condensing pressure to the evaporation pressure should not be too large, so that the gas temperature is too high at the end of the compression and the gas transmission coefficient of the compressor is lowered.

The refrigerant solidification temperature is low to prevent the refrigerant from solidifying at the evaporation temperature. The viscosity and density are small to reduce the flow resistance loss of the refrigeration system. The high-temperature cycle machine has a high thermal conductivity to increase the heat transfer coefficient of the heat exchanger and reduce the heat transfer area and metal material consumption.

The refrigerant adiabatic index is small, which can reduce the power consumption of the compression process. At the end of the compression, the gas temperature is not too high, and the liquid heat capacity is small. The loss of the throttling process can be reduced, and the thermal perfection of the cycle is as large as possible. It does not burn, does not explode, is non-toxic, does not corrode to metal, does not have chemical action with lubricating oil, does not decompose under high temperature and is harmless to human body.

There are many types of refrigerants for high and low temperature cycle machines. The refrigerants used by different manufacturers are different. It is recommended that users choose environmentally friendly refrigerants better, energy saving and environmental protection.

Похожие рекомендации

-

Tips on how to save energy for enterprises using industrial chiller

1672Nowadays, energy conservation has been advocated, and power consumption has always been a concern for everyone. Everyone knows that industrial equipment consumes electricity. For many chemical material manufacturing enterprises, the pressure of th...

Посмотреть детали -

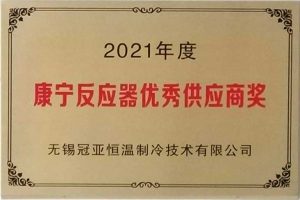

Победа в номинации "Отличный поставщик оборудования для контроля температуры реактора в 2021 году"

4630LNEYA was awarded the "2021 Excellent Supplier of Reactor Technology" by Corning, a Fortune 500 company in the United States. Since 2015, LNEYA has won this award for 7 consecutive years. Therefore, in the reactor manufacturing industry, we have ...

Посмотреть детали -

Current status of hot and cold rapid temperature change test chamber

1654At present, manufacturers of hot and cold rapid temperature change test chambers are sprouting like spring bamboo shoots, but there are several manufacturers that really grasp the quality. When purchasing a test box, the buyer must first look at t...

Посмотреть детали -

Что нужно учитывать при покупке системы охлаждения двигателя с масляным охлаждением?

1651Purchasing objects is nothing more than based on several types of methods: inquire with people around you, search and consult on the Internet by yourself, so that you can avoid some detours. 1. Parameter requirements: Ordering from the Internet is...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик