Why does the glass reactor need a heating refrigeration circulator in use?

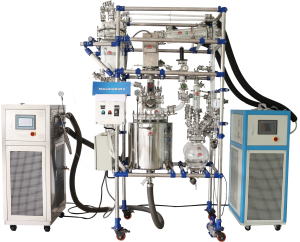

The glass vacuum reactor is of double-layer glass design. The inner layer is filled with reaction solvent for stirring reaction, and the interlayer can be connected with different cold and heat sources (freezing liquid, hot water or hot oil) for circulating heating or cooling reaction. Under the condition of constant temperature, the stirring reaction can be carried out under atmospheric pressure or pressure dependent conditions according to the use requirements in a closed glass reactor. It can do the reflux and distillation of the reaction solution. It is an ideal pilot and production equipment for modern fine chemical plants, biopharmaceuticals and new material synthesis.

The glass interlayer interface is connected with hot oil for circulation, which can be used for reaction under high temperature; The reaction at low temperature can be carried out by adding coolant. It can also be connected with water, which can quickly take away the reaction heat.

The interlayer inlet and outlet on the glass reactor can be heated with hot oil and low-temperature reaction with coolant. If steam is used for heating, it shall not exceed 0.5k-1k. (Note: try not to use pressure steam heating).

High temperature circulator shall be used for heating and low temperature circulator shall be used for refrigeration. Before use, add reaction materials for heating or cooling. Avoid that there is no material in the reactor and heating or cooling is carried out in the interlayer.

If the reactor needs heating or cooling, the high-temperature circulator or low-temperature circulator should be used for circulating heating or cooling. It is forbidden to heat and recycle or refrigeration and recycle first.

To cool down the reactor at high temperature, first turn off the heat switch of the high temperature circulator (the circulation switch remains on), add water or oil, and gradually cool down with the temperature in the circulator. Do not pump out the heated substances in the interlayer of the reactor, and directly cool down the circulating new substances.

Lneya heating refrigeration circulator can realize dynamic temperature control from – 45 ℃ to 250 ℃, and has heating and refrigeration function. It is equipped with two LED display controllers, which can display the set temperature value, actual value and over temperature alarm value at the same time. The product is efficient and fast, and the liquid filling is simple. The whole liquid circulation is a closed system without oil mist and water absorption, which ensures the safety of the experiment and the service life of the heat conduction medium. International brand compressor and circulating pump are adopted, with stable performance and reliable quality; The product has self diagnosis function, refrigerator overload protection, high-voltage pressure switch, overload relay, thermal protection device and other safety protection functions. It ensures the machine itself and the glass reactor, and improves the quality of reaction results and the service life of the equipment. Contact us for details sales@lneya.com obtain.

Похожие рекомендации

-

What is the local overheating machine room water chiller?

1608What is the local overheating machine room water chiller?

Посмотреть детали -

Чип ИС выделенный холодильный нагрев тест машины инструкции

1676Полупроводниковый чип Chiller - это симулятор температурных испытаний, используемый в тестировании полупроводников. Как профессиональный производитель, LNEYA имеет широкую температурную ориентацию и высокую температуру подъема и спада, а диапазон температур составляет -92 ° C ~ 250 ...

Посмотреть детали -

[Invited to visit] CPHI CHINA 2019, Wuxi Guanya W5P22 booth is looking forward to your arrival!

1937On June 18-20, 2019, the 19th World Pharmaceutical Raw Materials China Exhibition - CPhI China 2019 will re-enter Shanghai New International Expo Center. CPhI China World Pharmaceutical Raw Materials China Exhibition is an international, high-qual...

Посмотреть детали -

What are the components that improve the performance of industrial chillers?

1859Industrial chillers are indispensable equipment in LNEYA production. With its normal operation, we will have better work efficiency and higher product quality. The refrigeration system of an industrial chiller is mainly composed of four core compo...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик

![[Invited to visit] CPHI CHINA 2019, Wuxi Guanya... [Invited to visit] CPHI CHINA 2019, Wuxi Guanya...](https://www.lneya.com/wp-content/uploads/2023/05/20190612134416-300x144.jpg)