Как выбрать модель термостата для литографической машины?

How to choose a suitable industrial chiller, and what aspects should be paid attention to in the design of the unit?

1. Choose air-cooled or water-cooled temperature control device for lithography machine

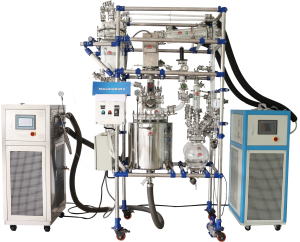

The condensation methods of industrial chillers are divided into air-cooled and water-cooled. The corresponding equipment is often called the temperature control device of the lithography machine. The selection must first consider whether the air-cooled condensation method is suitable

2. Determine cooling capacity demand

It is necessary to calculate the cooling capacity required for the actual application of the temperature-controlled equipment, which can usually be directly determined according to the cooling capacity or compressor power requirements provided by the customer, or it can be estimated according to the actual process conditions and experience. It should be noted that Generally speaking, the refrigeration capacity of the temperature control device group of the lithography machine refers to the rated refrigeration capacity, which also needs to be calculated in conjunction with factors such as the actual ambient temperature.

3. The choice of evaporator

evaporator type: coil evaporator / shell and tube evaporator / plate heat exchanger

Material of evaporator: Whether the liquid to be cooled (refrigerant) has anti-corrosion requirements such as acid and alkali resistance, and special materials such as stainless steel and titanium tubes are required.

4. Selection of circulating water pump

The flow rate and head of the chilled water circulating pump in the temperature control device group of the lithography machine should be determined in combination with the application equipment piping, installation distance, temperature control accuracy and other factors.

There are many other aspects that need attention in the selection of the temperature control device of the lithography machine, such as the power supply voltage, whether the refrigerant has environmental protection requirements, etc., I will not repeat them here.

Похожие рекомендации

-

Небольшой переворот для борьбы с ледяным затором в высоко- и низкотемпературных жидкостных циркуляционных охладителях

1296In the operation of high and low temperature liquid circulating chillers, ice blockage is a relatively common fault. Based on the experience of relevant manufacturers, we have specially compiled relevant tips for dealing with ice jams. In the pip...

Посмотреть детали -

Инструкции для производителей холодильных плит [от -5 до -150 градусов холода]

1689Существуют различные производители низкотемпературного низкотемпературного морозильника. Он широко используется в стеклянных реакторах, металлических реакторах и биореакторах для контроля температуры и температуры.Использование диапазона низкой температуры холодной пластины FreezerMediu...

Посмотреть детали -

Performance Characteristics of 30 HP Water Cooled Chiller

1710The 30p water cooled chiller is an industrial water chiller with a horsepower of 30 HP. The water-cooled industrial water chiller must rely on the cooling water tower for work, while the air-cooled industrial water chiller uses its own fan for coo...

Посмотреть детали -

What are the components that improve the performance of industrial chillers?

1866Industrial chillers are indispensable equipment in LNEYA production. With its normal operation, we will have better work efficiency and higher product quality. The refrigeration system of an industrial chiller is mainly composed of four core compo...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик