Почему для специальных газов, используемых в процессах производства полупроводников, требуются охладители?

If you have any questions, please contact us

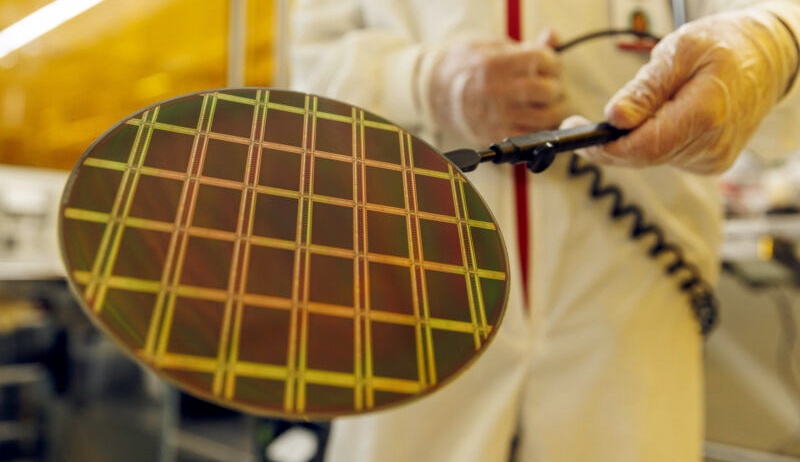

When using special gases in semiconductor manufacturing processes, a chiller is required, mainly due to the following reasons:

- Gas purity control: Special gases are used as raw materials in semiconductor manufacturing, and their purity is crucial to the performance of the final semiconductor device. Some special gases are prone to decomposition or react with impurities such as oxygen and water vapor at high temperatures, reducing their purity. The low-temperature environment provided by the chiller helps maintain the purity of gas during storage and transportation.

- Gas transportation and storage: Some special gases are easy to store in a liquefied state

Transportation, chillers can be used to cool gases to low temperatures, liquefy them, and facilitate storage and metering. Meanwhile, a low-temperature environment is beneficial for slowing down the natural evaporation rate of gases and reducing losses.

3. Process requirements: In semiconductor manufacturing processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), atomic layer deposition (ALD), etc., gas needs to go through a pre-treatment system, including a cooling system, before entering the reaction chamber to maintain gas transport at a specific temperature and prevent gas preheating or premature reaction in the pipeline.

4. Equipment cooling: Semiconductor production equipment generates a large amount of heat during operation, and requires a chiller to provide cooling for its internal gas delivery pipelines, reaction chambers, and other components to ensure that the gas maintains a stable temperature when entering and leaving the chamber. This is crucial for precise process control and product quality.

5. Safety considerations: Some special gases may become unstable or flammable and explosive at high temperatures. Using a chiller can reduce the risk of gas leakage accidents and ensure the safety of the entire process.

Therefore, the chiller is crucial for the storage, treatment, and use of special gases in the semiconductor manufacturing process, and is one of the key equipment to ensure the smooth progress of the semiconductor manufacturing process.

Request a quote

Предоставляем 7*24 бесплатных консультаций и комплексных решений

Похожие рекомендации

-

Buying Tips of Ultra Low Temperature Freezer

1642As for the industrial refrigerating treatment, the ultra low temperature freezer is indispensable. Let me tell you something about it!The ultra low temperature freezer of Wuxi Guanya Refrigeration technology co., Ltd is mainly used in industrial r...

Посмотреть детали -

Accessories and accessories for heating and cooling systems

1749The selection of heating and cooling system is quite important, not only price and temperature control, but also quality should be taken into consideration. Besides, you should also pay attention to the accessories of heating and cooling system. F...

Посмотреть детали -

How to maintain stable performance of biopharmaceutical laboratory oil cooler?

14171. A suitable working environment to prevent various failures of the oil cooler in the biopharmaceutical laboratory needs to provide a better operating environment for the equipment. Keep the environment clean and tidy, reduce the impact of vario...

Посмотреть детали -

Explosion-proof cryogenic refrigeration unit icing, do you know what is going on?

2038When using an explosion-proof cryogenic refrigeration unit, many users do not know how to solve the problem of icing and frosting. In fact, the professional can tell you with certainty, no. The two causes are different, so the processing method is...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик

Отправить на консультацию

Мы ответим вам в течение 24 часов