Как выбрать трубопровод для конденсационной адсорбционной регенерации вокс?

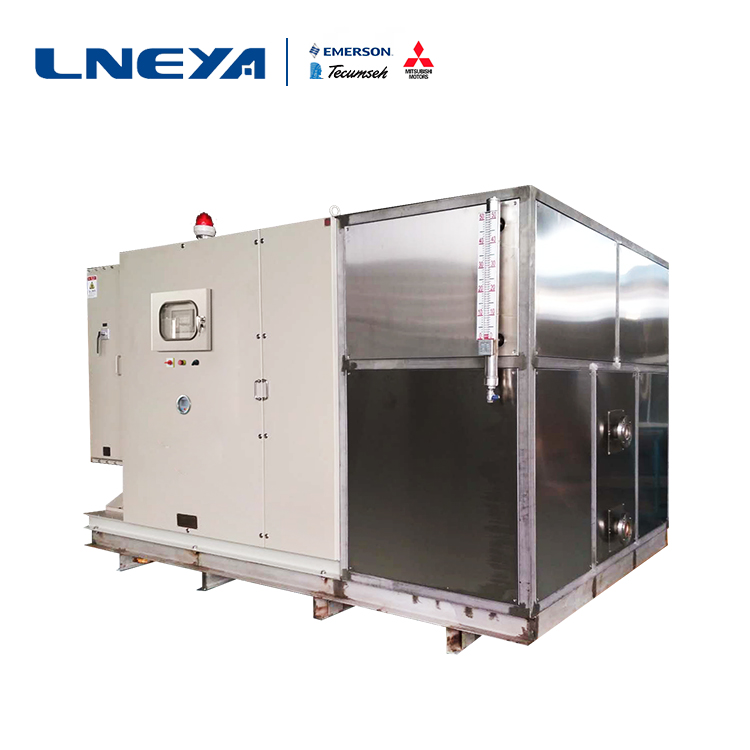

Condensate adsorption recovery vocs device at the time of selection, its system configuration needs to be clear to be able to buy with confidence, then, the condensation adsorption recovery vocs pipeline attention points, how to choose?

Condensate adsorption recovery vocs should be as short as possible in the pipeline connection with the controlled substance, reduce bending, when the pressure of the circulation pipeline is too large, the pipeline pressure is insufficient, it will cause the pipeline, the reactor to crack, high temperature, The possibility of spraying low-temperature heat-conducting medium may cause injury, burns, frostbite and ignition of flammable materials, pollution caused by loss of reactants, property damage, and even poisoning of personnel.

The pipeline connection should be sealed and firm, and it has measures such as anti-vibration, grounding, rust prevention and pressure keeping. It can effectively prevent the pipeline from vibrating and corroding, causing cracks and leakage, and there is a danger of static electricity.

Condensate adsorption recovery vocs When connecting with controlled equipment, pay attention to the link of the pipeline, do not have the interface error, generally the liquid outlet corresponds to the inlet, the inlet is connected to the outlet, if it is water-cooled, The water outlet corresponds to the water return port, the water inlet corresponds to the water outlet, and the liquid discharge port (used when the heat medium is replaced) corresponds to the waste liquid collection and collection port.

In the selection of the pipeline, if the use of improper / damaged hoses and / or hose joints, it will lead to personnel injury, it is recommended that the metal insulation hose temperature range -60 ~ 250 ° C; pressure ≤ 2.5 bar.

Condensate adsorption recovery vocs When you carefully configure the metal insulation hose and other pipelines, please refer to their pressure and overpressure capabilities, caliber, and temperature range. At this time, it is necessary to consider the head pressure of the circulating pump inside the equipment. It is recommended that the condensing adsorption recovery vocs should select a pipeline of good quality and sufficient volume such as seamless steel pipe.

When selecting insulation materials, the temperature range of condensing adsorption recovery vocs should be considered first. It is necessary to select the flame retardant material. The temperature range of the insulation material should include the temperature range of the equipment, and there is a margin greater than 30 °C. When the user ignores this problem, There is a possibility of fire. There is also a sufficient amount of insulation material package for condensing adsorption recovery vocs, otherwise the equipment control will not achieve the expected results.

Each component of the condensing adsorption recovery vocs device is very important for its performance. Therefore, it is recommended that the user select the specific parameter configuration and then make a decision when selecting the condensing adsorption recovery vocs.

Похожие рекомендации

-

The role of chiller in the manufacturing process of catalytic materials

1641In the field of new material preparation, by accurately controlling the reaction temperature, the influence of different temperatures on the microstructure and macroscopic properties of materials can be explored, thereby developing new mat...

Посмотреть детали -

Air-cooled and water-cooled methods of cooling and heating circulators

1816The cooling heating circulator is controlled by high and low temperature during operation. After the user runs at high temperature and low temperature, it can be heated with heat transfer oil, which is water-cooled and air-cooled. 1. It belongs ...

Посмотреть детали -

Купить TCU-Multiple Reactor Cooling Heating Temperature Control System

1951Researchers who do research work know that during the laboratory experiments, TCU-multiple reactors are often used for cooling and heating temperature control systems or high and low temperature all-in-one machines, so TCU-multiple reactions that ...

Посмотреть детали -

Chip test system analysis why chip test?

1833Functional failure means that a function point is not implemented. This is often caused by design. Usually, it is verified by simulation before the design stage, so usually a chip is designed and the simulation verification takes about 80% of the ...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик