Description of the action of the filter in the ultra-low temperature compressor unit

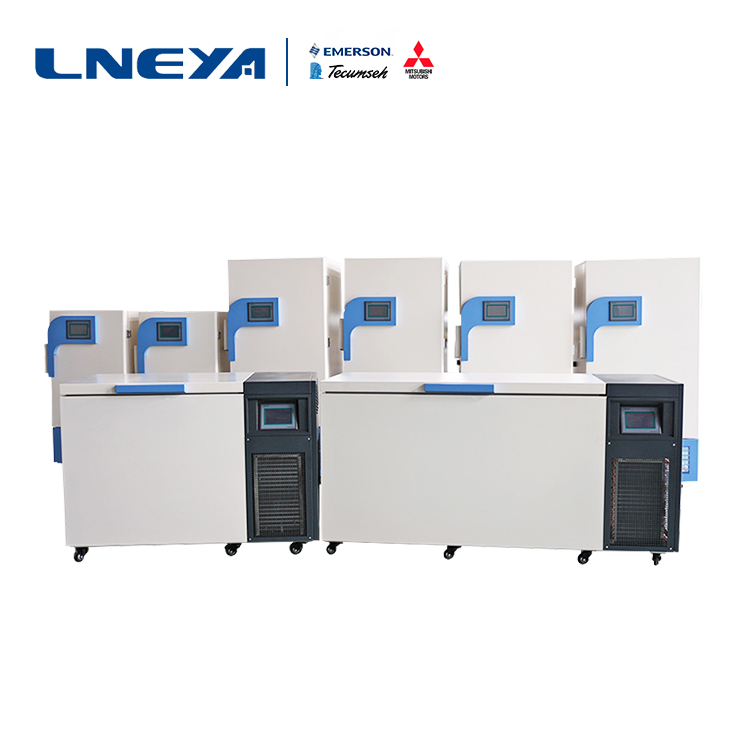

In order to stabilize the operation of the ultra-low temperature compressor unit, the performance of the compressor is very important, and in addition to the compressor, the filter is also important.

In order to maintain normal operation, it is necessary to ensure the normal use of the refrigerant. In the entire ultra-low temperature compressor cycle system, the refrigerant cannot be completely unaffected. During the normal cycle operation, the refrigerant will contain more and more. Metal scraps, as well as other magazines, are inevitable in normal operation.

However, if the refrigerant contains these impurities, it will definitely affect its normal operation, which will seriously affect the overall refrigeration quality of the ultra-low temperature compressor unit. At the same time, it will cause damage to the compressor and other components. Therefore, the refrigerant needs to be filtered. This is the filter. Play a role.

Ultra-low temperature compressor set filter refers to the device that provides filtration service for the refrigerant. Usually it is put together with the dryer. It is two-in-one, but the filter itself can be cleaned, cleaned and replaced separately. In general, in industrial ultra-low temperature compressor units, there must be a filter device. The filter does not have any deep design, that is, through the extremely dense mesh device, the metal debris and other materials in the refrigerant. Impurities are filtered.

The function of the filter is simply to clean the refrigerant and allow the refrigerant to be recycled many times. If there is no filter, the refrigerant can not be recycled normally. It may be a few days later. The maintenance of the filter also requires a snack. The frequency and various aspects of the filter in the ultra-low temperature compressor group under different environments and different operating intensities are also different. Secondly, if conditions permit, it is recommended to replace the filter once a month, or three months later, otherwise it will affect the use of the filter.

Of course, the different types of filter models of the ultra-low temperature compressor group are also different, and the user can select the corresponding condenser according to the specific working conditions.

Похожие рекомендации

-

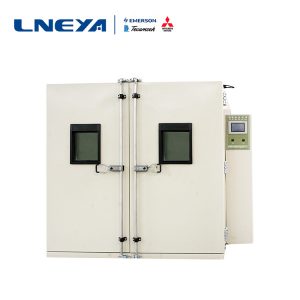

Description of the characteristics of the LNEYA walk-in test chamber

1369Wide temperature control range can meet the user's various needs.Unique balanced temperature control method, a stable and balanced heating capacity can be used for high precision and high stable temperature control.The temperature displayed by tou...

Посмотреть детали -

Refrigeration heating circulator list resonance fault description

1834Refrigeration heating circulator leaderboard works: When the temperature of the reactor, reactor, rotary evaporator, extraction equipment, etc. of the refrigeration heating circulator needs to be rapidly increased or lowered, the equipment can qui...

Посмотреть детали -

Description of high and low temperature circulation tank refrigeration process

2047In the process of using high and low temperature circulating tanks, there may be some minor problems due to improper use, and there may be problems in the refrigeration process of Wuxi Guanya high and low temperature circulating tanks, and then we...

Посмотреть детали -

Этиленгликолевая холодильная установка произвела мощное наступление и создала бренд LNEYA за 12 лет

2021Позиционирование с улучшенными характеристиками При выполнении реакции охлаждения и нагрева во многих случаях хладагент не может сам охладить охлаждаемый объект. Поэтому необходим хладагент (или хладагент) для охлаждения холодильной системы в ре...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик