Способы повышения энергоэффективности сверхнизкотемпературных циркуляционных охладителей

In modern times, environmental protection

and energy saving is the development theme, so is the industrial chiller. Then,

how to improve your industrial chiller to be more energy conservation?

First, to prevent and reduce the pipe

scaling of ultra low temperature recirculating chillers is for enhancing the

heat transfer efficiency of condenser and evaporator.

If the make-up water is treated badly,

calcium carbonate and magnesium carbonate produced by calcium bicarbonate and

magnesium bicarbonate through heating will precipitate on the pipes, decreasing

the heat-conducting property to have an impact on the heat exchange efficiency

of condenser and evaporator and increase the electric charge by a large margin

for chiller’s operation. Apart from using water treatment technology, that you

can apply the equipment for cleaning the pipes regularly, which can save the

electric quantity and at the same time level up ultra low temperature

recirculating chiller’s effect.

Second, to adjust the operating load of ultra

low temperature recirculating chillers reasonably.

By terms of ensuring the industrial chiller

to operate safely, power dissipation of an amount of cold

energies are smaller. It should consider the operating situations of water pump

and cooling tower comprehensively while taking this method into effect.

Third, to lower condensing temperature of

ultra low temperature recirculating chillers.

On the premise of meeting the requirement

including the security of cooling-water machine and production demand, evaporating

temperature should be raised and condensing temperature should be lowered as

much as possible. Please allow me to have your attention that the cooling tower

needs to make a big change so as to keep the efficiency.

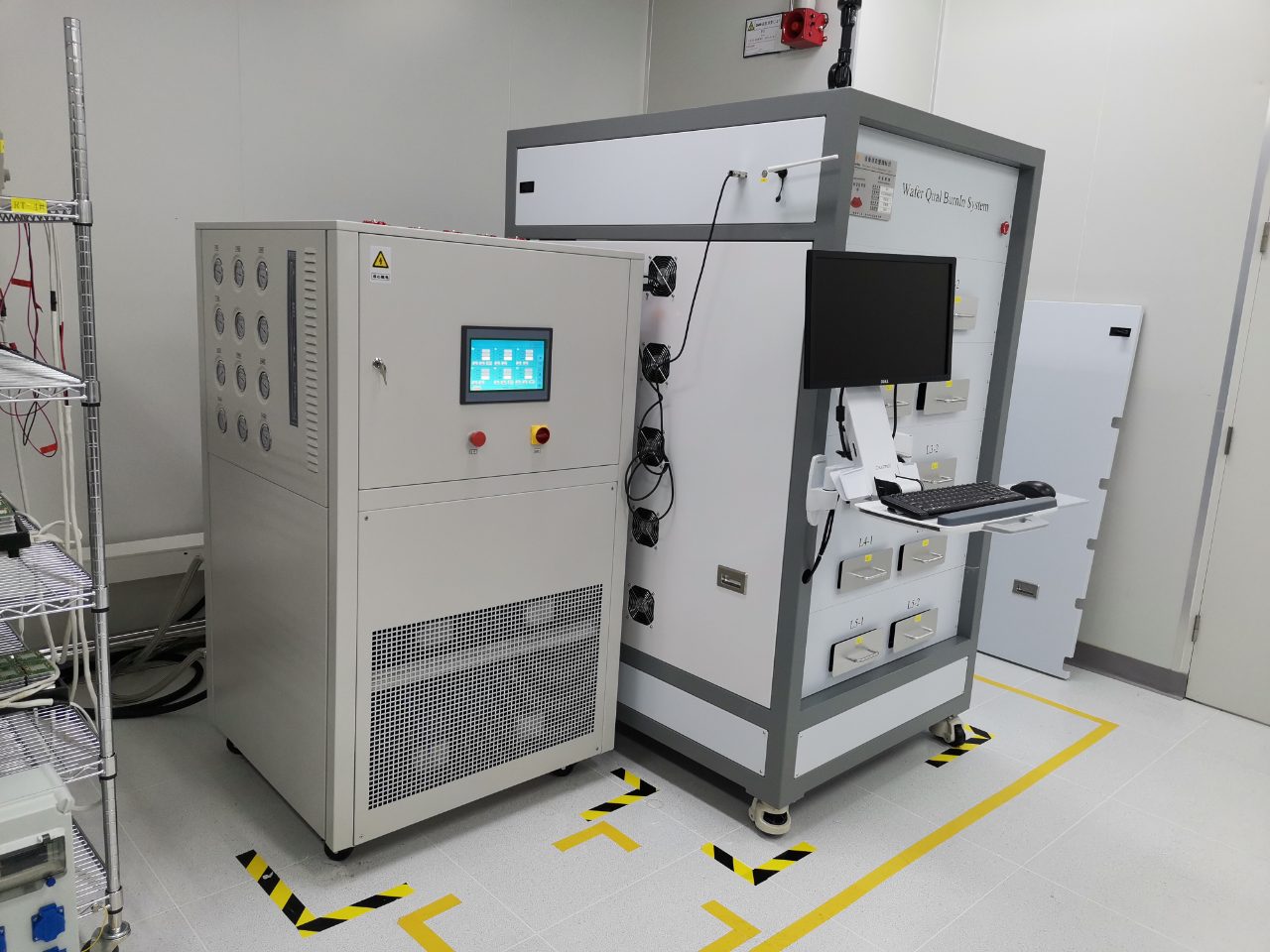

Industrial chillers divide into many

categories like screw chiller, air-cooled water chiller, water chiller and

ultra low temperature recirculating chillers. I am pleased to claim that the

energy conservation of chiller is realizable. You can contact us by

email:sales@lneya.com.

Похожие рекомендации

-

LNEYA isolation explosion-proof cooling heating circulation system SR-35N

1092LNEYA isolation explosion-proof cooling and heating circulation system mainly uses heat transfer medium for heating and refrigerant for cooling. So what are the main accessories in the isolated cold and hot water circulation system? What effect do...

Посмотреть детали -

Closed circulation cooling system debugging attention note

1655Closed circulation cooling system needs to pay attention to some common problems during commissioning. Do a good job in debugging work. LNEYA manufacturers remind users that only when they are ready to work can they be better debugged. The prepara...

Посмотреть детали -

Influence of refrigeration factors on high temperature enclosed explosion-proof industrial chillers

1748Check whether the high and low temperature enclosed explosion-proof industrial chiller is the cause of its own failure. The selection must be accurate. If the model is not in place, the required refrigeration effect will also not be achieved. It i...

Посмотреть детали -

Советы по выбору бренда для ультранизкотемпературного морозильника

1403Когда речь заходит о сверхнизкотемпературном морозильнике, большинство людей начинают беспокоиться, потому что сверхнизкая температура означает, что технология становится более сложной. По сравнению с другими хладагентами, выбор ультранизкотемпературного морозильника...

Посмотреть детали

LNEYA Промышленные чиллеры Производитель Поставщик

LNEYA Промышленные чиллеры Производитель Поставщик